Frederick, MD Industrial Explosion Protection Systems

Industrial Explosion Protection in Frederick, MD

With over 40 years of experience, SysTech Design provides industrial explosion protection solutions tailored to the unique needs of chemical facilities, food processing plants, and fabricated metal operations in Frederick, MD. Our explosion protection systems are engineered to meet NFPA explosion protection standards and OSHA requirements, ensuring both safety and compliance. We understand the hazards posed by combustible dust and industrial explosions, and we implement solutions that reduce risks while maintaining productivity. From explosion isolation valves to explosion vents and suppression systems, our designs protect process equipment and personnel from catastrophic events. We approach every project with a thorough risk assessment, identifying potential hazards and integrating systems that provide a strong defense against dust explosions. Evaluating these hazards in the early stages of industrial process planning or installation is essential to ensure the most effective safety measures are implemented. Our team focuses on protecting your assets while ensuring smooth, uninterrupted operations. At SysTech Design, industrial safety is more than a requirement—it’s our commitment to every client. SysTech Design is recognized as a world leader in industrial explosion protection, delivering world-class standards and expertise to every project.

Our Industrial Explosion Protection Solutions

Explosion Isolation in Frederick, MD

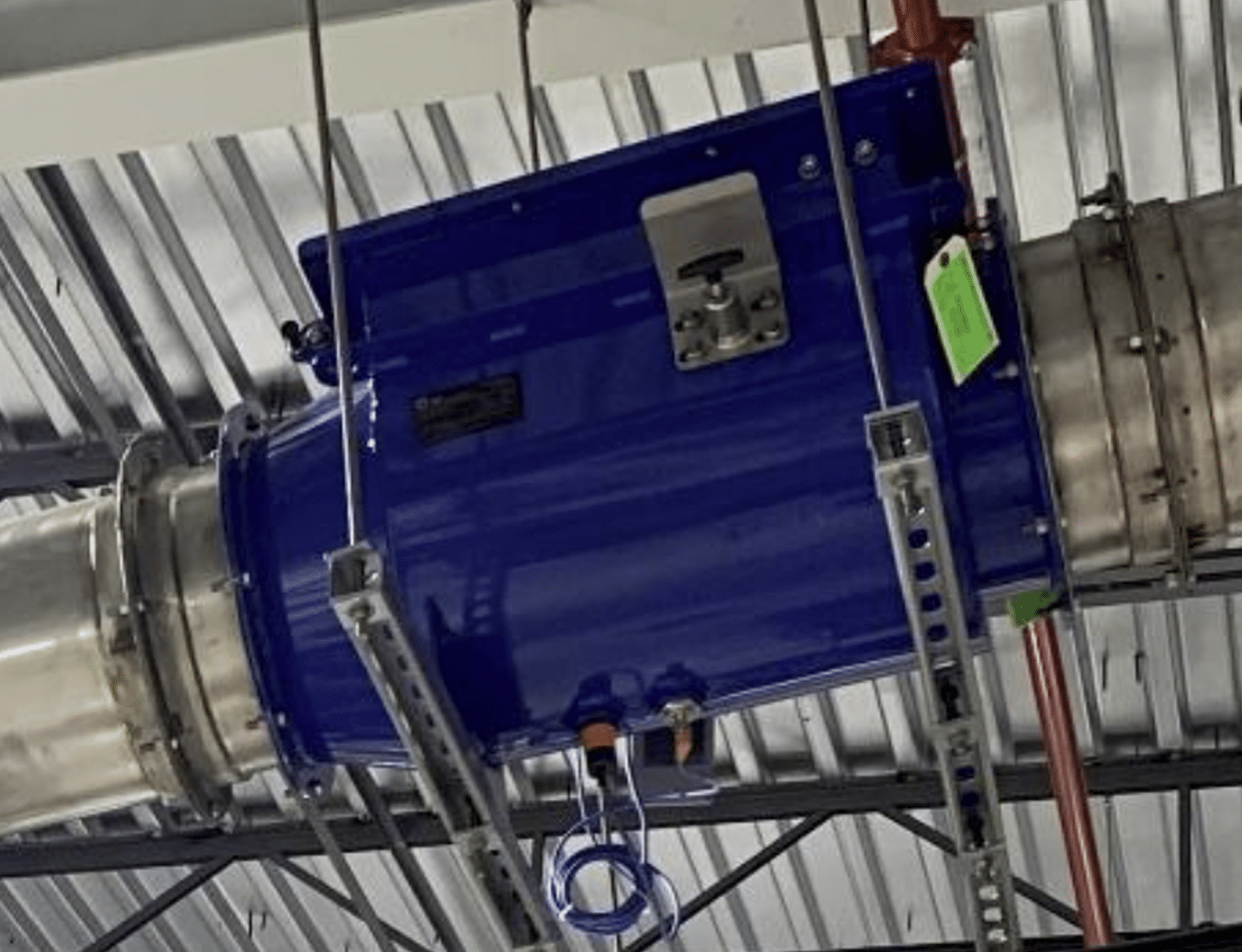

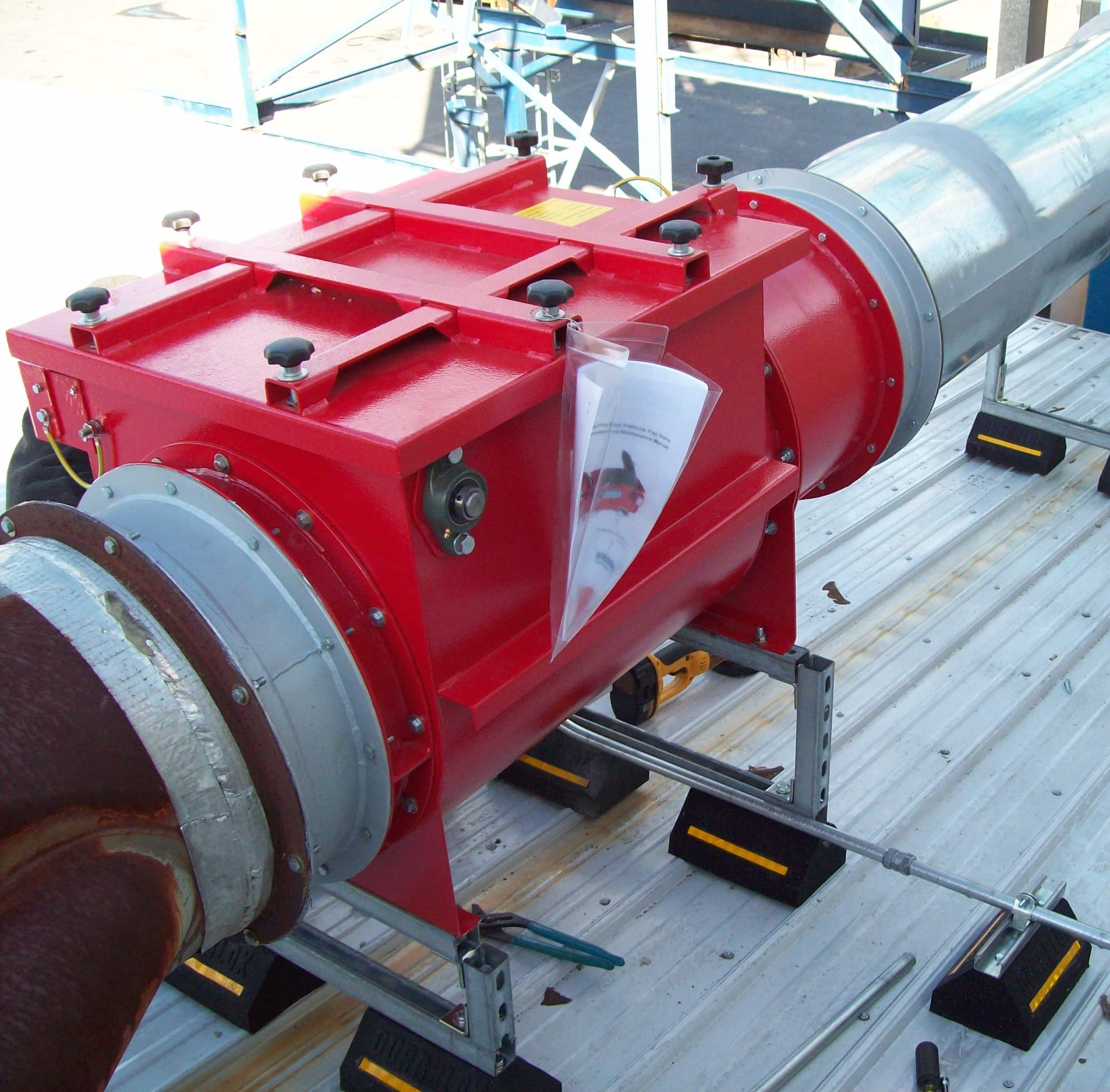

Explosion isolation systems are critical in stopping an explosion pressure wave from spreading through connected equipment and ductwork. At SysTech Design, we provide explosion isolation valves and explosion isolation flap valves that are designed to protect dust collectors, conveyors, and other vulnerable process equipment. To ensure effective protection, these devices must be properly installed on process equipment in various installations. These systems help prevent secondary dust explosions and maintain the integrity of your facility. Whether you operate in food manufacturing, chemical processing, or metal fabrication, our explosion isolation systems enhance overall safety and regulatory compliance.

- Reduce secondary explosion risks in processing plants – Prevents the spread of flames and pressure into other facility areas.

- Protect vital equipment such as dust collectors and conveyors – Shields expensive process equipment from severe damage.

- Improve facility safety and regulatory compliance – Meets OSHA and NFPA explosion protection system requirements.

- Stop explosion pressure waves from spreading through ducts and pipelines – Blocks dangerous pressure surges and flame fronts.

Contact us today to see how explosion isolation vents can help contain industrial explosions in Frederick.

Explosion Suppression Systems in Frederick, MD

Our explosion suppression systems are designed to detect and extinguish explosions within milliseconds, minimizing damage and downtime. SysTech Design uses advanced sensors and control units to monitor pressure and flame changes in real time. When an explosion is detected, suppressant agents are rapidly injected into the vessel through specialized nozzles to quickly cool the fireball, stop ongoing combustion, and mitigate the effects of the explosion. These systems are ideal for industrial settings where combustible dust explosion protection is essential, such as in silos, mixers, and dust collectors. By using non-toxic suppressant agents, we ensure both safety and product quality in food and chemical facilities. Explosion suppression not only saves equipment but also protects workers from the dangers of an explosion event.

- Advanced sensors and control units for immediate detection – Provides instant monitoring of explosion indicators.

- Ultra-fast response time to stop explosions within milliseconds – Halts explosion propagation before significant damage occurs.

- Reduced downtime and equipment loss after an event – Keeps your operations running smoothly after an incident.

- Non-toxic suppressants that effectively extinguish explosions – Safe for use in sensitive industrial applications.

Click the button below to browse our complete selection of explosion suppression equipment in Frederick.

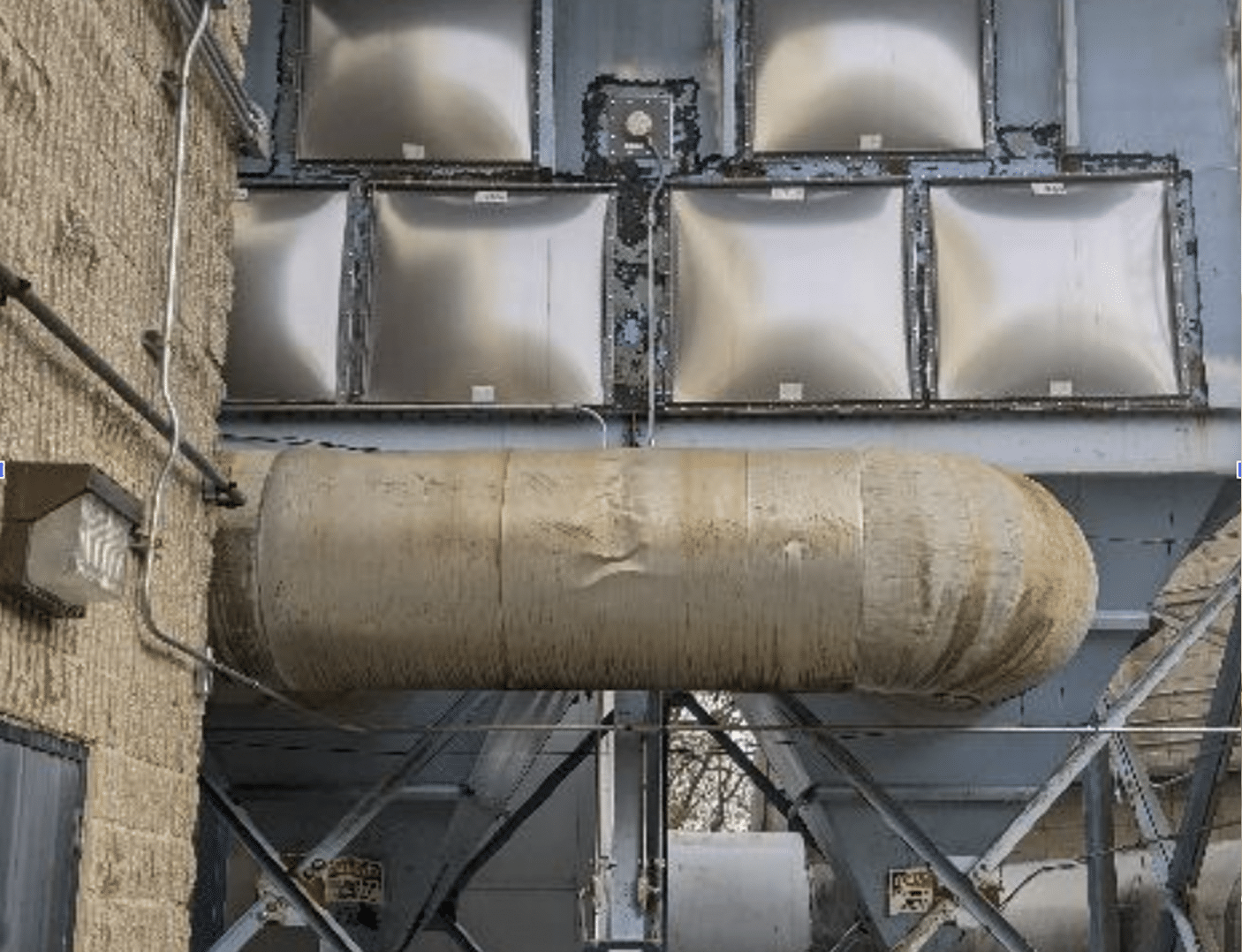

Explosion Vents in Frederick, MD

Explosion vents offer a cost-effective and reliable way to control explosion pressure in process equipment such as dust collectors and silos. When an explosion occurs, these devices activate to relieve overpressure within the vessel, minimizing the risk of catastrophic failure. Explosion vents are designed to open at a predetermined pressure, safely venting explosive forces to a designated safe area and protecting both personnel and equipment. SysTech Design provides industrial explosion vent panels that are engineered to meet NFPA explosion protection standards and OSHA regulations. We offer both standard vents and flameless vent options for indoor applications where open flame release is not permitted. Certain vent panels are suitable for vacuum conditions and can be used in a variety of installations, including OEM and retrofit setups. The installation process is straightforward and offers low installation costs. By integrating our explosion vents with existing process equipment, we ensure a seamless and compliant safety solution.

- Ensure compliance with NFPA and OSHA regulations, standards, or proven strategies – Designed to meet stringent industry codes.

- Prevent catastrophic structural failure in dust collectors, silos, and processing equipment – Releases static burst pressure in a controlled way.

- Integrate seamlessly with existing industrial systems – Works with your current process equipment without costly modifications.

- Direct explosive forces safely away from personnel and equipment – Guides explosion forces toward a designated safe location.

Get in touch with us today to request a quote on explosion vents in Frederick.

The Importance of Industrial Explosion Protection for Frederick Facilities

Industrial explosion protection is essential for facilities that handle combustible dust, including chemical, food, and fabricated metal manufacturing plants. Without proper explosion protection equipment, a single dust explosion can cause severe injury, equipment loss, and costly downtime. SysTech Design offers complete explosion protection systems, combining explosion isolation, suppression, and venting to safeguard your operations. Our approach addresses both OSHA explosion protection requirements and NFPA explosion protection standards, ensuring you remain compliant while reducing risk. With decades of experience, we know how to design systems that protect lives, equipment, and production efficiency. By investing in effective explosion mitigation systems, Frederick facilities can operate with confidence in their safety and reliability.

Why Choose SysTech Design for Explosion Protection?

Industry-Leading Expertise

SysTech Design is a premier provider of explosion protection systems in Montgomery County. Our team has years of experience and a wide breadth of knowledge.

End-to-End Support

From start to finish, your project will be managed by a single team, ensuring a seamless purchase, delivery, and installation process.

Proactive Compliance

We don’t just help you meet current regulations—we ensure your facility is prepared for evolving safety standards, keeping you at the forefront of innovation and worker safety.

Proven Track Record of Success

From manufacturing to chemical processing, our solutions have protected industries nationwide, delivering measurable safety improvements.

Custom Solutions

We offer custom-designed explosion protection systems for Montgomery County industries, tailored to their unique needs and operating conditions.

Comprehensive Support

From initial hazard assessments and system design to the final installation, we provide end-to-end explosion protection solutions that safeguard your workforce and operations 24/7.

Explosion Protection Solutions We Offer in Frederick, MD

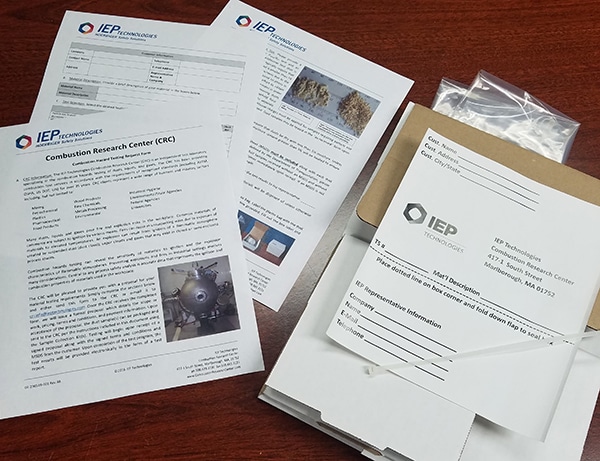

Combustible Dust Testing

Explosion Vents

Explosion Suppression

Explosion Isolation