SysTech is experienced in developing industrial noise control strategies that meet OSHA and NIOSH regulations for a wide range of industrial environments and manufacturing sites. Noise is a big problem that companies need to keep working on, whether it’s inside a building and affecting the workers or outside a building and affecting the people who live nearby.

Read about our noise attenuation techniques, the products and systems we use, and the manufacturers we most commonly work with.

“Noise in an industrial environment can be a difficult, but necessary, problem to tackle. SysTech has the experience and products to achieve regulatory (OSHA) and/or municipal compliance to noise regulations and ordinances.” – Matt Glover 2009

Occupational & Outdoor Noise Control

Occupational noise is regulated in the workplace and corrective steps are documented to protect employees in the workplace from excessive exposure. Specifically, employees who encountering continued excessive noise levels might develop hearing loss and high-stress levels along with compromised safety issues.

Industrial non-occupational environmental noise compliance is typically defined by attenuation requirements or noise impact at a critical receptor point or at the property line. The noise source may be construction activities, manufacturing/production operations, or upset condition alarms. Agencies governing this type of noise are typically at the local level, but this can vary by state and municipality. Typical ordinances include:

- Allowable noise levels during daytime or nighttime hours

- Classification of areas into residential, commercial or industrial

- Defined decibel levels deemed to be acceptable for each category

How does SysTech address these potentially adverse acoustic issues?

Methods for Industrial Noise Control

Noise attenuation is achieved by decreasing the intensity or volume of sound in a controlled environment. There are many noise reduction strategies that can be employed in industrial settings. One of the most effective and logical approaches to noise attenuation is to install systems that minimize noise from the start, using control techniques such as:

- Damping – A method of reducing noise levels from chutes, hoppers, machine guards, conveyors, panels and more

- Selecting efficient equipment – Selecting fans, compressors, PD blowers and engines that operate efficiently contribute significantly to noise attenuation

- Adjusting Fan Speed – Fan noise is in direct correlation with fan speed, so simple adjustments can produce significant results

- Controlling high-pressure steam, natural gas, and other vent noises

- Attenuating noise from process exhausts with stack silencers

- Acoustically treating fans, blowers, and ventilating equipment

- Closing openings in enclosures and barrier walls required for utilities

Methods for Industrial Noise Control

Noise attenuation is achieved by decreasing the intensity or volume of sound in a controlled environment. There are many noise reduction strategies that can be employed in industrial settings. One of the most effective and logical approaches to noise attenuation is to install systems that minimize noise from the start, using control techniques such as:

- Damping – A method of reducing noise levels from chutes, hoppers, machine guards, conveyors, panels and more

- Selecting efficient equipment – Selecting fans, compressors, PD blowers and engines that operate efficiently contribute significantly to noise attenuation

- Adjusting Fan Speed – Fan noise is in direct correlation with fan speed, so simple adjustments can produce significant results

- Controlling high-pressure steam, natural gas, and other vent noises

- Attenuating noise from process exhausts with stack silencers

- Acoustically treating fans, blowers, and ventilating equipment

- Closing openings in enclosures and barrier walls required for utilities

Noise and Vibration Control Engineering Services

Field sound level testing is an available service.

Knowing and defining the noise intensity, those impacted by the noise, and who is requesting noise controls be put in place are all essential parts of a noise control solution. It is critical to determine the extent of the noise issue before formulating an attenuation scheme.

And it is important to remember that when a single piece of machinery needs to be attenuated, knowing the other noise producers in the vicinity and the building construction impact the final noise solution.

Some of our services, offerings, and tasks include:

- Noise modeling

- Analysis and attenuation of “noisy” machines and process equipment

- Noise and vibration engineering design, research, and control

- Sound intensity measurements

- Sound power measurements

- Plant noise surveys

- Community noise surveys

- Rotating equipment measurements

- Structure-borne noise and vibration analysis

- Noise source analysis and control

- Noise source identification and measurement

- Zoning compliance measurements

- Noise barrier design

- Occupational noise measurements

- Noise enclosure design

- Personnel sound booths and control room design

Industrial Noise Control Products and Systems

The environmental impact caused by industrial processes such as vent blow-offs, rooftop fans and HVAC equipment, chillers, cooling towers, oil and gas building ventilation systems, power gen engines, and other noise generating processes can be addressed by installing various types of noise abatement equipment. We partner with the leading manufacturers of industrial noise control products and systems to offer a broad range of reliable industrial noise control solutions.

Industrial Fan Silencers – Fans are found in almost all industrial applications and can be large contributors to the problem of industrial noise. Exhaust and supply fan silencers can significantly reduce noise in both indoor and outdoor environments.

Acoustic Louvers – Where ventilation air is required, addressing noise concerns from a processing area within a building or machinery noise mitigation from a facility, acoustic louvers are a proven means of attenuation.

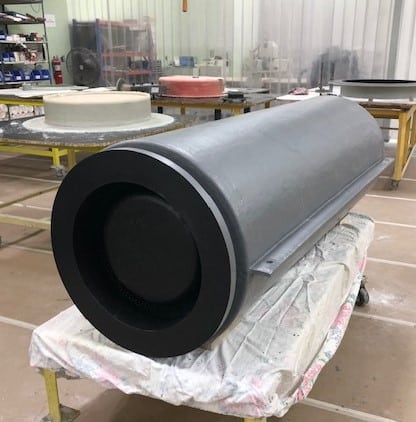

Industrial Exhaust Silencers – In addition to selecting the right noise control equipment, SysTech will access the entire noise attenuation application and reduce the overall sound level. Process silencers are applied to PD blower and compressor exhausts, stack discharges, and the venting or blow-off of high-pressure gases.

Noise Control Enclosures – Engineered acoustically for superior noise control, sound enclosures are an extremely effective means for containing industrial equipment noise.

Duct Silencer – Where noise radiates from a ducted system or enclosure, duct silencers are typically applied with success.

Acoustic Building Ventilation Systems – When very high equipment noise levels are present in a building caused by large compressors, engines, generators, and motors, and heat removal ventilation systems are required, SysTech offers customized acoustic ventilation systems to meet both ventilation and noise reduction requirements.

Duct Lining – Ventilation systems using acoustic absorbent material such as foam or fiberglass will effectively decrease airborne noise.

Vibration Isolation Pads – Vibration control, employing anti-vibration machine mounts such as springs or neoprene will reduce transmission of noise created by vibration.

Acoustic Flexible Connectors – They serve a dual purpose in containing noise generated by the fan blade rotation and that induced by vibration.

Acoustic Blankets/Wraps – Attenuate noise from the equipment casing with high-density sound blankets.

Industrial Noise Control Product Manufacturer

We represent the leading industrial noise control manufacturer and are able to offer a complete range of noise attenuation products to meet noise control needs or requirements.

VAW Systems Ltd.

VAW is an industry leader in the design and manufacturer of industrial noise control products. From industrial silencers on the intake or discharge of fans and blowers, to industrial-duty acoustic enclosures and barrier systems, they know what it takes to get the noise out. Also, they offer engineered vent and blow-off silences for air, steam, and natural gas along with custom designed packages for inlet filtration systems.

Food Blending Process Retrofit

Successful installation and start-up of a dust collection system by SysTech Design at a vanilla bean processing plant.View of dust collector, isolation valve, and fabricated hoodThe handling and blending of dry food powders is a typical operation at food processing...

Paint Booth Fan Noise Control

Paint booth packages are often purchased with integral axial exhaust fans. The exhaust fans come with an estimated pressure loss, which may not be application-specific because the booth (s) location is not always determined at the time of order. Most Original...

Pharmaceutical, Food, & Vitamin Manufacturing Weighing and Mixing Operation

Gummy or gummi products are more than candy and are increasingly popular for dispensing vitamins, supplements, medicines, food products, and cannabis. The essential ingredients to produce gummies include gelatin, cornstarch, water, and sugar, with drugs, vitamins, or...

Optional Industrial Noise Control Walkthrough, Inspection or Troubleshooting

Let SysTech be part of your Noise Abatement Solution

SysTech is experienced in developing industrial noise control solutions for a wide range of industrial environments. Call SysTech to discuss your industrial noise control needs.

Some Service Areas

Pittsburgh, PA | Blair County, PA | Bucks County, PA | Erie County, PA | Scranton, PA | Lancaster County, PA | Allentown, PA | Luzerne County, PA | Williamsport, PA | Lock Haven, PA | York County, PA | Baltimore, MD | Montgomery County, MD | Talbot County, MD | Washington County, MD | Baltimore County, MD | Essex County, NJ | Gloucester County, NJ | Morris County, NJ | Middlesex County, NJ | Fredericksburg, VA | Kent County, DE | New Castle County, DE