Axial flow fans or industrial axial fans use a propeller to draw the air into the fan then discharge it in the same axial direction which makes them advantages for small space constraints. The way these fans work is like the propeller on an airplane: the fan blades generate an aerodynamic lift that pressurizes the air. Axial fans are typically selected where large air volumes of clean air need to be moved against low static pressures. There are optional designs where vanes are added to the standard housing configuration are to allow the propeller to generate greater static pressure. They can be used in varying environments as they are available constructed of painted carbon steel, stainless steel, aluminum, or FRP.

Axial fans are commonly used for ventilation purposes, moving large amounts of air, against minimal resistance, through workplaces creating a desirable air change per hour to refresh air quality or modulate temperature. They are also used in process applications where axial flow is desired and static pressure is not excessive. Based on their placement in the duct system, they can be used in either a supply or exhaust configuration.

Expected Performance from Industrial Axial Fans

- Roof Ventilators to 135,000 CFM

- Duct Fans to 80,000 CFM and 6 inches WG

- Vane Axial Fans to 175,000 CFM and 10 inches WG

Axial Fan Optional Propeller Designs

- Fixed pitch – High efficient cast propellers

- Adjustable pitch – Blade pitch can be changed to modify performance

- Swept-back design – Improved performance design

- Low noise – Reduced noise levels

- Reversible – Can be used in a supply and exhaust application

Examples of Where Axial Fans are Used

- Paint Booth Exhaust

- Supply Ventilation

- Warehouse Exhaust Ventilation

- Process and spot cooling

- Heat Relief

- Furnace Exhaust

- Wastewater Pump Station Ventilation

Terminology for Industrial Axial Fan Designs

- Wall, Panel or Ring Fan

- Duct and Duct Axial Fans

- Vaneaxial Fan (adjustable pitch)

- Hooded and Recirculating Roof Ventilator

- Up blast Roof Exhauster

- Supply Intake Fan

- Smoke Ventilator

- Mine Duty Fan

- Marine Duty Fans

- Tube Axial Fan

- Personnel Cooler

- Air Circulators

Hooded Roof Ventilators

Tube Axial Fans

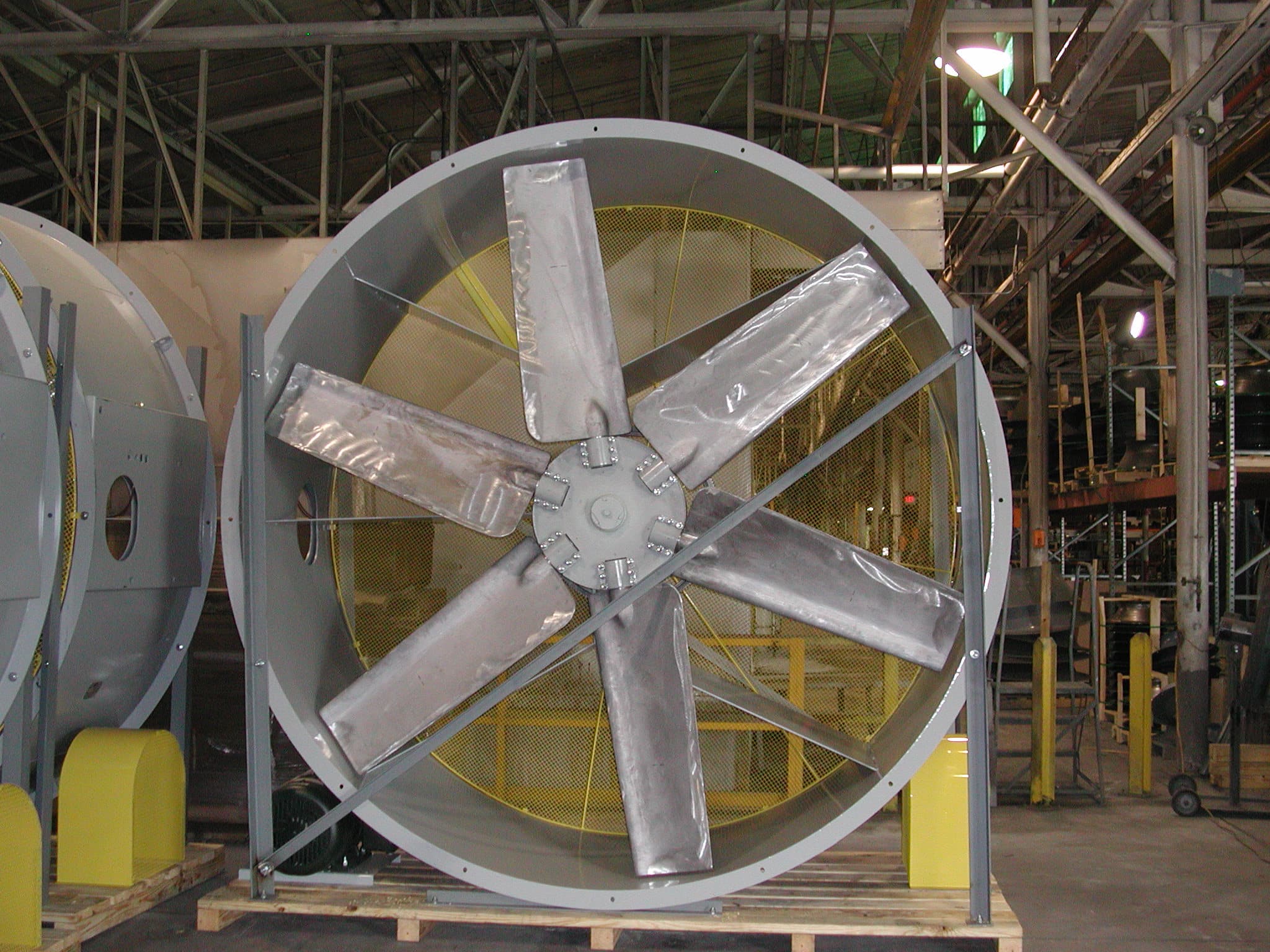

Tube axial fans are called duct fans, duct axial fans, and vane axial fans. They are fans where the impeller is contained in a short section of round duct. The impellers can be a fixed design or have adjustable blades and a vane section can be added after the fan for improved performance. They are available in both direct or belt drive and optional construction materials including carbon steel, aluminum, stainless steel, and FRP.

Wall or Panel Fans

- wall fans for crypto mining center exhaust

These are also called wall mounted exhaust fans, panel, or ring fans. Mounted vertically on a wall they draw air into or out of the workplace. If used as supply fans they typically have hoods and screens to prevent intake of debris, rain, or snowy weather. Readily available materials of construction include carbon steel, aluminum, stainless steel, FRP, and PVC.

HVLS Ceiling Fans

24′ Diameter High Volume Low-Speed Fan

High Volume Low Speed or HVLS Ceiling Fans, blanket very large areas such as a warehouse, with constantly moving air to create an expansive comfort zone. As a result, these large diameter ceiling fans (up to 24 feet in diameter) can create an evaporative cooling effect during the summer months while de-stratifying uneven floor to ceiling temperatures in the winter when heated air accumulated along the ceiling is moved down unto the workplace floor. This results in significant energy savings since the facility heating system cycles less frequently.

Call SysTech to discuss specific axial fans for your needs.