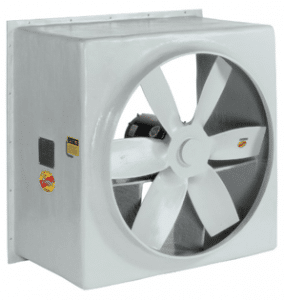

Fiberglass Exhaust Fans

Airborne corrosive mists and gases conveyed in process exhausts or present in the surrounding ambient environment, cause metal degradation, and promote premature equipment failure. The presents of compounds and gases such as hydrogen sulfide, ammonia, nitrogen oxides, hydrogen chloride, and chlorine, require construction using chemically resistant materials. Fan and blower construction might be a composite of polymer and fibers, a synthetic plastic polymer, or a grade of stainless steel. Stainless steel construction might be an acceptable alternative depending on the air stream chemistry, but a plastic composite construction is often recommended.

Fans and blowers of plastic composites, selected for severe duty applications, are most often constructed of FRP (Fibre-reinforced plastic), PVC (Polyvinyl Chloride), and PP (Polypropylene), with selection based upon temperature, airstream constituents, and particulate physical characteristics. We’ve found that FRP is the primary “go-to” design, followed by PVC and PP.

Plastic fans are vital for many industrial process applications where corrosive and chemically aggressive environments exist. SysTech selects and applies these plastic fans and blowers to provide:

- Maximum protection in an aggressive environment or air stream

- Cost efficiency

- Low noise

- Efficient operation

- Rugged durability

- Ease of maintenance

Fiberglass Exhaust Fan Performance

- General ventilation:

- Upblast & Downblast Exhausters are available in direct drive in sizes 12” to 60” and can handle from 1,315 to 55,500 CFM in temperatures up to 180°F. Centrifugal exhausters are available in direct or belt drive in sizes of 12” to 60” and can handle 500 to 22,000 CFM in temperatures up to 125°F. Upblast and Hooded Roof Ventilators are available in both direct and belt drive in sizes 12” to 40” and can handle from 1,260 to 73,330 CFM in temperatures up to 200°F. They also come with a hood or upblast option.

- Axial fans:

- Duct fans, typically used in low static pressure applications, are available in direct drive or belt drive in sizes 12” to 60” and can handle 1,325 to 66,700 CFM in temperatures up to 180°F. Duct axial fans are available in direct or belt drive in sizes 12” to 60” and can handle from 470 to 70,000 CFM in temperatures up to 180°F. Bypass or bifurcated fans are available in direct drive in sizes 24” to 48” and can handle 6,012 to 46,145 CFM in temperatures up to 200°F.

- Centrifugal fans

- Backward curved centrifugal fans are available in direct or belt drive in sizes up to 73” and can handle up to 130,000 CFM and up to 18” W.G. static pressure. In-line centrifugal fans are available in direct or belt drive in sizes 12” to 60” and can handle 100 to 14,659 CFM and up to 12” of W.G. static pressure. Radial pressure blowers are available in direct or belt drive in sizes form 10” to 33” and can handle 100 to 14,659 CFM.

Want to know what fan construction is required in your corrosive environment? Download the Material Corrosion Resistance Guide

FRP Exhaust Fans and Blowers

Plastic exhaust fans are mainly Fiberglass, with PVC construction available for some applications and cost savings. Fiberglass reinforced plastic or FRP exhaust fans and blowers are known for their ability to handle a wide range of corrosive applications and temperatures to 250 degrees Fahrenheit. FRP axial and centrifugal fans are designed for corrosive air stream applications in which metal fans will not withstand hostile environments or aggressive conditions. Fiberglass exhaust fans operate in corrosive applications with high efficiency and low noise characteristics and have the following features:

- Solid fiberglass housings

- High-pressure wheels available

- Abrasive-resistant coating available

- Surfacing Veil – Nexus is standard, C Glass optional

- One-piece die-formed FRP wheel

- Standard UV inhibitor and flame-retardant resin

- Encapsulated stainless steel hardware in the airstream

Where FRP Fans Are Applied

- Corrosive and Chemically Aggressive Ambient Plant Environments

- Acid Scrubbers

- Ammonia Scrubbers

- Plating Scrubbers

- Pickling Lines

- Acid Dip Tanks

- Pump or Lift Stations

- Chemical Processes

- Process Gases

- Sulfuric Acid Exhaust

- Chlorine Scrubber Exhaust

- Wastewater Treatment Plants – Download the Wastewater Treatment Plant Schematic

- Analytical Laboratories

- Battery Manufacturing

- Pharmaceutical Laboratories

- Pulp and Paper

- Chemical Plants

- Metal Finishing

- Lab Hood Exhaust

- Electroplating

- Precious metal recovery

Ancillary Equipment for FRP Fans

Complementing our fans is a complete package of FRP, PVC and CPVC air system components including:

- Supply and exhaust louvers

- Fan intake and discharge dampers

- Multiblade supply and exhaust wall dampers

- Dome exhauster covers

- Discharge stacks

- Duct, elbows, tees and complete duct manifolds

- Custom designed hoods

SysTech offers a wide selection of corrosive environment equipment. Let us match the correct materials of construction with your airstream constituents and assist with all your corrosive environment needs.