Ventilation for Corrosive Environments

Corrosion Resistant Materials

Corrosive gases that might exist in an industrial environment or airstream are Hydrogen sulfide, Chlorine, Sulphur dioxide, Ammonia, Ozone, Mercaptans, Hydrogen fluoride or Sodium hypochlorite. These are not the only gases that need to be dealt with, but they are the typical culprits of equipment erosion.

There are extremes of corrosion that occur, which requires special materials of construction. Those chemically resistant materials most commonly used for the construction of ventilation equipment is typified by the following:

Stainless Steel (SS) – Depending on the application, there are many ways SS fans and blowers can be constructed for high temperature, high moisture, and steam applications. Typically, 304 or 316 stainless steel are the materials for construction, but 304L and 316L are considerations based on the specific gas and the concentrations. Stainless steel fans are the most economical choice for corrosion resistance, but corrosion protection efficiency needs are determined first on the corrosivity of the gases in question. Should particulate be in the airstream, SS has advantages over other materials of construction.

Fiberglass (FRP) – FRP fans and blowers are utilized for general/process ventilation where corrosive environments contain unforgiving fumes or vapors. The material makeup of FRP fans typically provides tremendous efficiency in these environments. The material composition of FRP fans offers strength at extremely low temperatures and the ability to withstand temperatures up to 250⁰ F. Hartzell Air Movement FRP Fans have a unique one-piece design resin molded wheel and fiberglass components in the airstream provide fans with extreme durability, higher strength-to-weight ratio, and a lighter product compared to metal fans. They offer important options of additional abrasive/erosion resistant coatings, H-Cor extra corrosion synthetic surface veil, and electrical grounding.

Polyvinyl Chloride (PVC) – Similar to FRP fans, PVC fans (with polypropylene wheels) typically provide good protection for many corrosive applications. They are more fragile/weakened with decreasing/increasing temperatures than FRP. PVC/polypropylene fans typically have no metal pieces in contact with the air stream and are suitable up to 140⁰ F. Fans constructed of polypropylene can reach higher temperatures than PVC fans because of more flexible material which also provides a stronger and flame-retardant product. Both fans are constructed using a vacuum-formed thermoplastic process indicating a highly accurate blower each time. Contrasting with FRP fans, PVC/polypropylene fans often are a more economical option.

Polypropylene – Resistant to many acids, caustic, and inorganic saline products used in labs. Like PVC fans but are suitable up to 190⁰ F.

Where Corrosive Environments are Expected

Some form of a corrosive atmosphere or airstream is typical in some facilities or processes including but not limited to:

- Wastewater Treatment Plants and Hydrogen Sulfide (H₂S) – Due to the extremely aggressive nature of wastewater and the chemicals used to treat it, many of the by-products released into the air through wastewater treatment, attack metallic components. The primary gas to be concerned about is Hydrogen sulfide (in addition to mercaptans and amines) and is found in the sludge drying room, lift stations, grit chambers, and FRP is the material of choice for most fans and blowers in these areas.

- Chemical Plants – Many chemical processes generate corrosive gases which result in corrosive issues. These corrosive materials can range from gases/vapors to solids and often disperse into the air during processing. A careful selection of construction materials is undertaken after a complete understanding of the constituents in the airstream or ambient environment.

- Pulp & Paper and Chlorine (Cl) – There are production steps within this industry, including pulping, pressing, and bleaching, that create an opening for a highly corrosive environment. We know the predominant corrosive gases in this industry are Chlorine and Chlorine Dioxide with equipment selection designed to handle these at a minimum.

- Facilities near coastal and marine environments – Saltwater (the Sodium Chloride content) accelerates the oxidation of iron and steel resulting in equipment deterioration and failure.

Where corrosive materials are used in processing, the ambient air within the area will also have a concentration of these materials. It is important to consider this when choosing the correct ventilation equipment for your application to avoid capital equipment losses.

Corrosion Resistant Ventilation Equipment

To help mitigate the losses of capital equipment by using proper equipment construction, there are many ventilation products for corrosive environments:

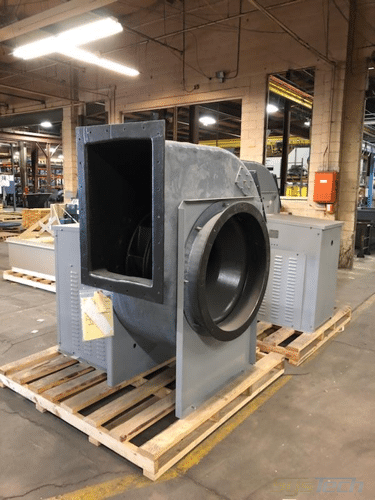

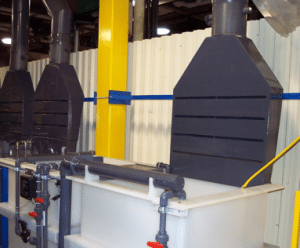

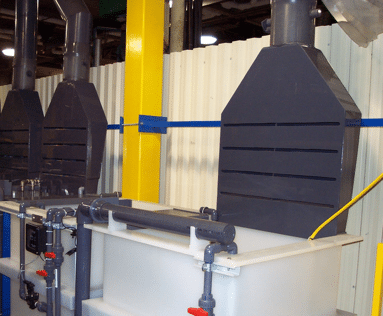

- FRP Fans and Blowers – Mainly used in severe-duty applications because of its rugged durability while also being cost-efficient, low noise, and allowing for easy maintenance.

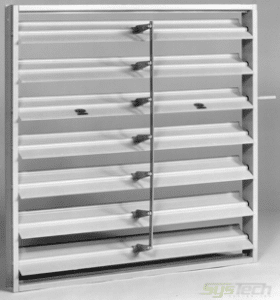

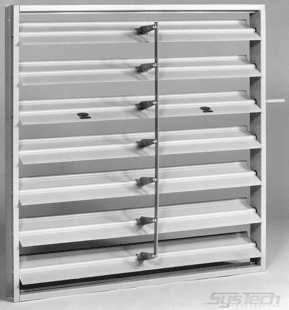

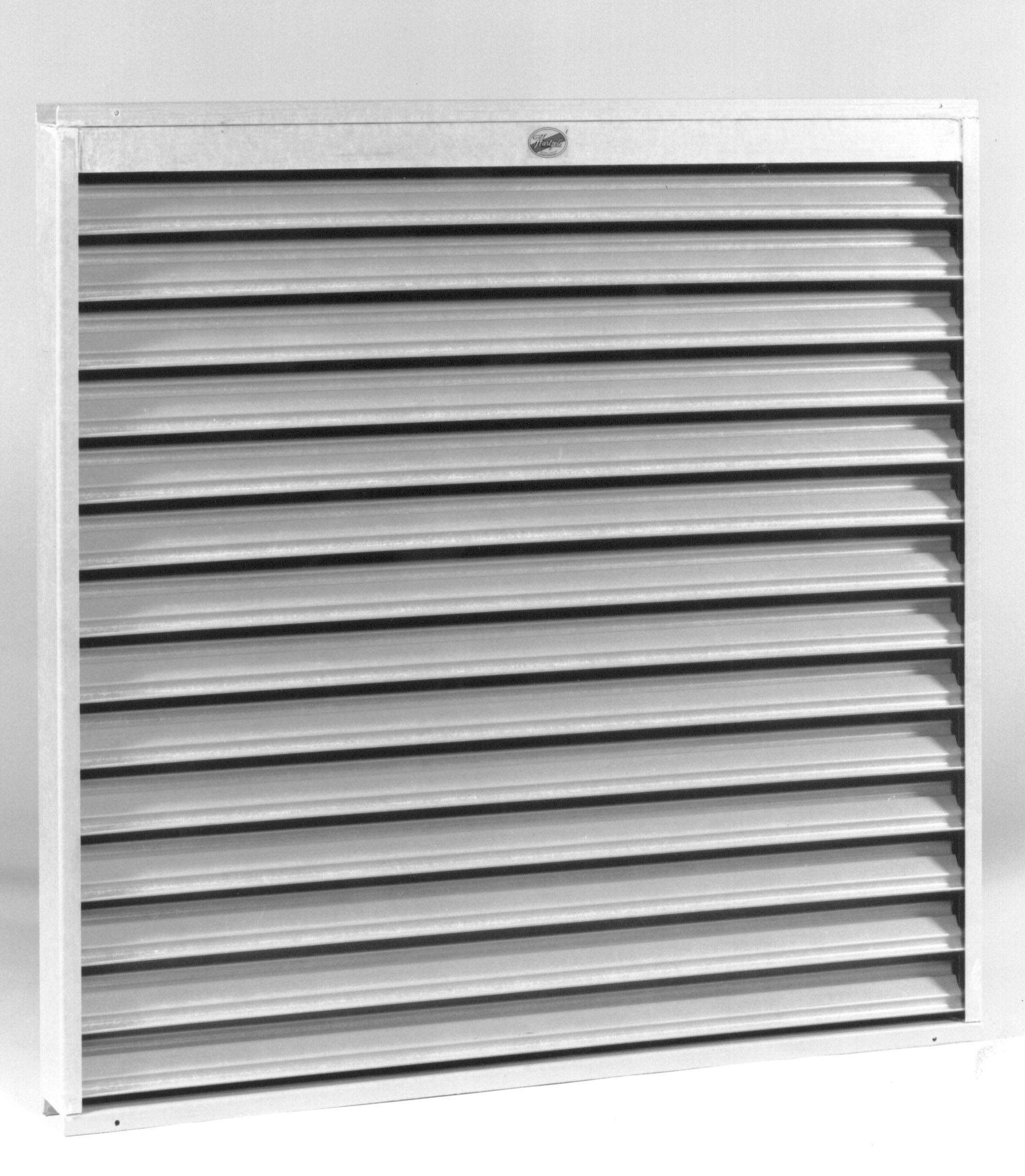

- FRP Dampers – Primarily used on fan inlets or outlets to control airflow or in exhaust ductwork in extremely corrosive environments.

- PVC Fume Exhauster Fans – Commonly used plastic fans for the efficient conveyance of corrosive, chemically-laden, humid, or polluted gases, fumes, and air in laboratories and chemical transfer stations. Well suited for hostile environments in which coated metals fail.

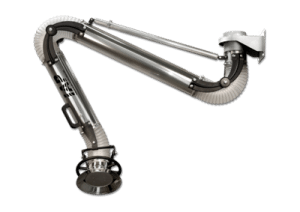

- PVC & FRP Duct Systems – FRP hoods and duct is an excellent choice for corrosion-resistant duct, hoods, and PVC duct systems provide exceptional chemical resistance to acids, bases, and salts while operating at maximum temperatures ranging from 140 to 200 degrees F.

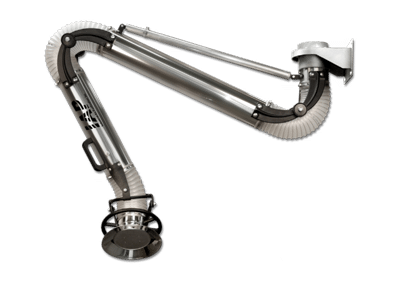

- Stainless Steel Fans – When handling corrosive gases and particulate at elevated temperatures or for blower applications with high-pressure requirements, stainless steel 304, 304L, 316 and 316L materials of construction are the proper selection.

- FRP Silencers – Inlet and outlet noise attenuators constructed of fiberglass (FRP) for airstreams that contain corrosives and condensation.

Equipment Manufacturers for Corrosive Environments

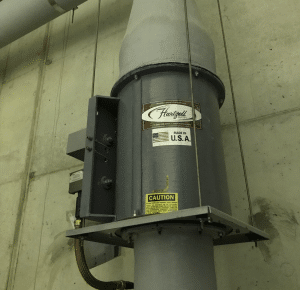

Hartzell Air Movement – Hartzell products include fans and blowers for both general and process ventilation including a complete line of axial fans, centrifugal fans and blowers, and an extensive fiberglass product line which includes FRP fans, blowers, louvers, and dampers.

Industrial Plastics Fabricators Ltd – IPF Limited is a manufacturer of custom fabricated plastic and fiberglass contact molded products, specializing in chemical applications & pollution control equipment.

IPF Colasit – IPF manufactures PVC blowers and polypropylene blowers that are well suited for use in corrosive environments, having high degrees of humidity and moisture, as well as high concentrations of caustics, chlorine, or acids.

VAW Systems – VAW supplies noise silencers constructed of FRP for the inlet or outlet of fans, blowers, scrubbers, and other process equipment.

SysTech offers turnkey solutions to your unique corrosion resistance process requirements. We have application experience and welcome the opportunity to share it with you.