Noise Control Enclosures

Tackling noise at its source(s) with noise control enclosure packages will effectively contain and reduce plant-wide levels. A highly effective means for controlling localized industrial noise is the installation of an encapsulating noise control enclosure around a source such as a hammer mill or compressor, to contain and absorb the noise to an acceptable level and at the same time, not interfering with the process equipment access or production schedule. Because almost every in-place noise issue is in a different plant environment or from a specific piece of machinery, each application requires custom design for the enclosure and with an understanding of the surrounding noise sources and building structure.

There are two (2) basic categories of enclosures based on construction materials used. Both are applied to sound enclosure applications such as:

- Containment of machinery

- Process enclosures

- Facility dividers

- Diesel and electric pump sets

- Movable screens

- Engine housing

- Compressor/pump/fan enclosures

- Factory quiet areas

- Control rooms

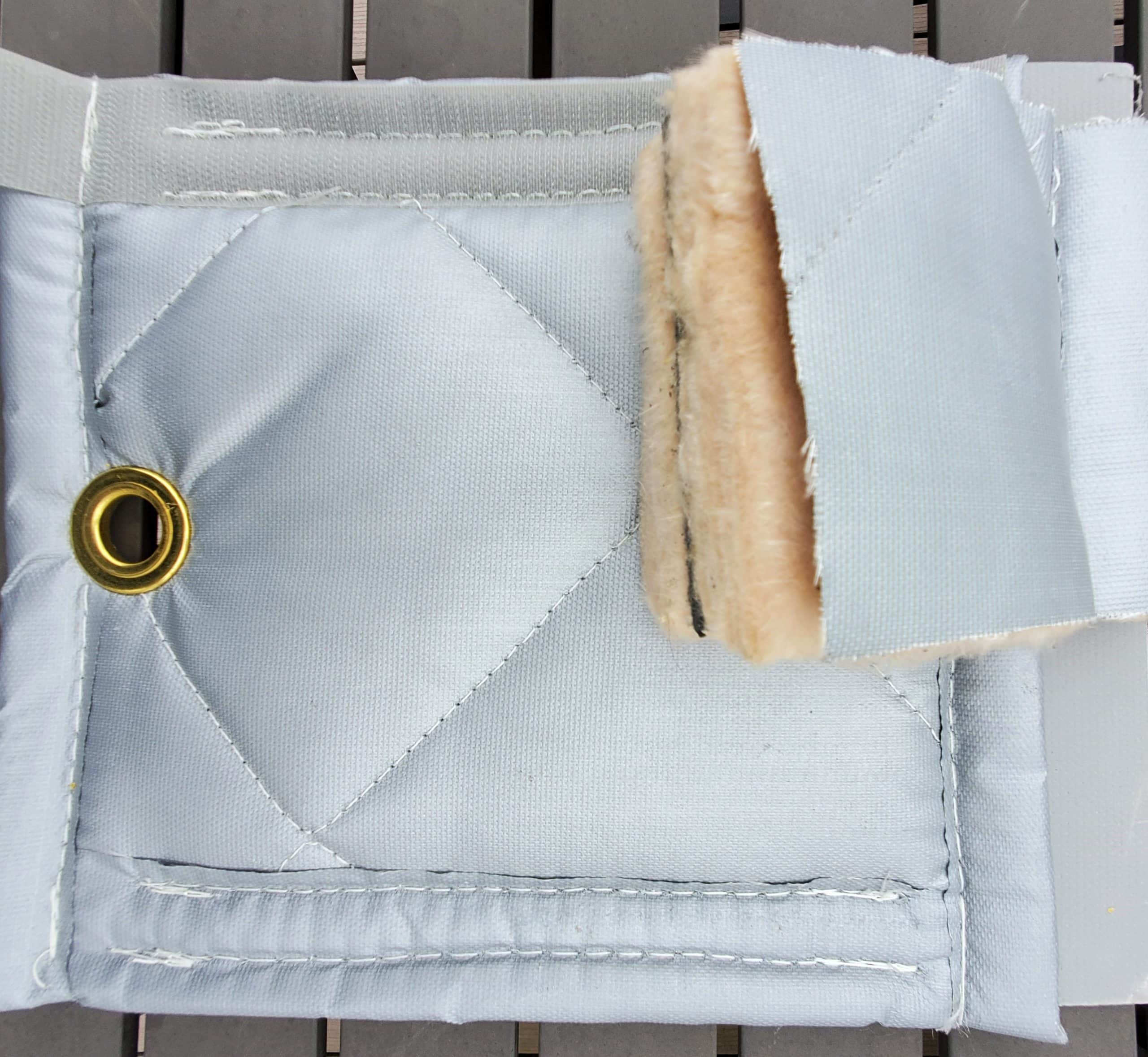

Noise Control Curtain Systems

Attaching flexible curtains to a tubular frame assembly provides an efficient noise control system. The soundproofing curtain systems are an economical, high performance, noise control product possessing high mechanical strength. They are fire safe, easily cleanable, resistant to dust, dirt, oils, and most chemicals, and give a long service life. Curtains reduce reverberant noise energy and offer a 7-10 dB reduction. Curtain enclosures sometimes referred to as “softwall” noise enclosures, are available which combine a high-mass noise control barrier with a lightweight acoustical fiberglass absorber, are designed to both contain and absorb noise, and offer an average of 12-15 dB reduction.

Options include:

- Grommets and/or Velcro on edges

- Steel framing (self-supported or ceiling mounted)

- High-temperature and outdoor facings

- Decorative facings

- Standard or custom colors

- Clear view windows

- Roof systems

- Access panels and doors

- Vent kits

- Tracked panels for quick movement

Benefits of a noise control curtain enclosure include:

- Quick access

- Replacing a damaged panel is quick and easy

- Movable

- Durability – with chemical and oil resistance

- Cost-effectiveness – compared with metal enclosures

- Easy assembly – no special installation required

- Flexibility – movable and reusable

- Fire safety – with low smoke configurations

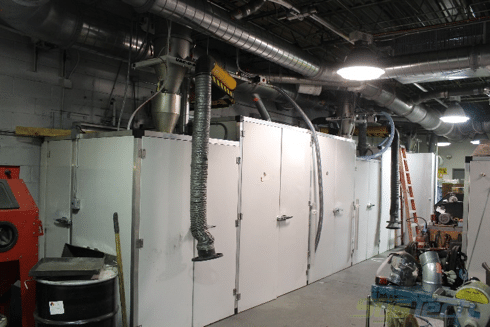

Noise Control Steel Panel Enclosures

Another effective means to attenuate a noise source is a rigid metal enclosure. Our standard wall panel is constructed of an 18 gauge solid exterior skin with a 22 gauge interior perforated liner, and a 4 lb/cu. ft. density acoustic fill core. With a Standard Tempering Core (STC) of up to 41, metal enclosures are designed to both contain and absorb noise and act as a barrier between noisy and quiet areas. The attenuation expected is 20 to 25 dBA. Options for other types and widths of wall construction are available. Options include:

Another effective means to attenuate a noise source is a rigid metal enclosure. Our standard wall panel is constructed of an 18 gauge solid exterior skin with a 22 gauge interior perforated liner, and a 4 lb/cu. ft. density acoustic fill core. With a Standard Tempering Core (STC) of up to 41, metal enclosures are designed to both contain and absorb noise and act as a barrier between noisy and quiet areas. The attenuation expected is 20 to 25 dBA. Options for other types and widths of wall construction are available. Options include:

- Clear-view windows used to view machinery in operation

- Roof systems

- Ventilation systems for heat removal

- Louvers and ventilators

- Access panels

- Single or double-seal doors

- Custom cut-outs to accommodate existing gauges, hoses, valves, and conduit

- Outdoor and high-temp models available

FRP Noise Control Enclosures

Where corrosive gases or aggressive environments exist such as in water, wastewater, or chemical plants, a noise enclosure having an FRP shell is a viable option. These enclosures are often constructed to NBS PS 15-69.,SMACNA and/or ASTM standards with a premium grade corrosive resistant, fire retardant resin and chopped strand glass, with a final UV inhibited Gel-coat exterior finish. The enclosure can be fabricated in multiple sections and has a 3 inch flange around the base. The enclosure has interior walls that are lined with foam for an attenuation from 10 to 15 dBA.

Options include:

- Clear view windows

- Ventilation fan for heat removal

- Access panel or door

- Inlet acoustic louver

- Custom cut-outs to accommodate existing gauges, hoses, valves, and conduit

- Custom color

- 316 stainless steel fasteners

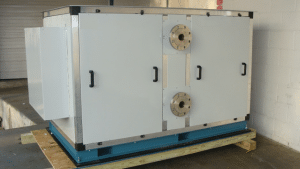

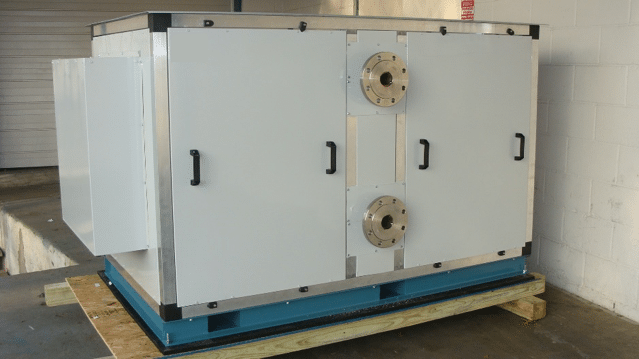

Noise Enclosure Panels for Air Handling Units

Noise control for air handling units can be applied to reduce the sound levels from the air handler fan. The air handler’s sides and the top would have a double-wall construction with internal fiberglass insulation. The noise enclosure panel thickness would be based on attenuation requirements. Along with the walls, the inlet and outlet duct from the air handler would be evaluated and treated as required.

SysTech offers both standard and custom-designed sound enclosure systems and can help you to determine the best sound enclosure option to suit your needs.

Noise Control Enclosures

An Integral Part of an Industrial Ventilation System

Acoustic enclosures are an essential part of a noise mitigation program where isolation of a noise source is obtainable. The attenuation possible and the flexibility of these enclosures to equipment maintenance needs, make them a valuable tool for plant noise mitigation programs.