Fan Balancing

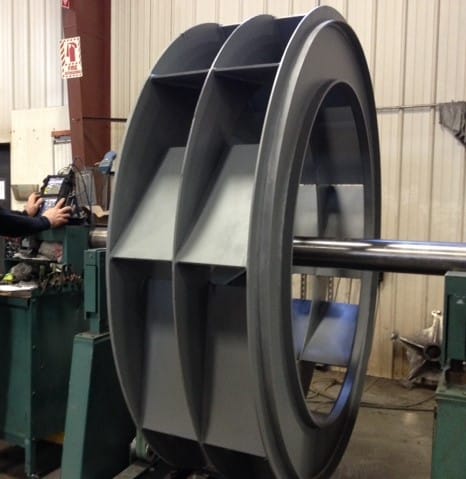

Precision Industrial Fan Balancing for Maximum Efficiency

We provide expert fan balancing services to enhance the performance, reliability, and longevity of your industrial fans. Our dynamic and static fan balancing techniques minimize vibration, noise, and mechanical stress, ensuring your equipment operates at peak efficiency.

The Importance of Fan Balancing

Industrial fans are crucial for ventilation, cooling, and air circulation in manufacturing plants, warehouses, and industrial facilities. Over time, factors like dust buildup, component wear, and environmental changes can lead to fan imbalance, causing:

- Increased energy consumption

- Premature wear on bearings and motor shafts

- Excessive vibrations and noise

- Unexpected breakdowns and costly repairs

- Reduced airflow efficiency

Regular industrial fan balancing prevents these issues, reducing operational costs and extending the lifespan of your equipment.

Common Causes of Fan Imbalance

A fan becomes unbalanced when the center of mass shifts away from the axis of rotation, creating undue stress on mechanical components. The most common causes include:

- Dust and debris accumulation

- Worn, bent, or damaged fan blades

- Improper installation or misalignment

- Temperature fluctuations and environmental factors

- Manufacturing defects or assembly issues

Ignoring these problems can lead to equipment failure, increased downtime, and safety hazards. That’s why proactive fan balancing services are crucial for maintaining efficiency and reliability.

Our Comprehensive Fan Balancing Process

At SysTech Design, we use cutting-edge technology and precision techniques to deliver effective on-site and in-shop fan balancing. By addressing fan imbalance proactively, we help you achieve lower maintenance costs, improved equipment performance, and a safer work environment. Our balancing process not only prevents mechanical failures but also ensures long-term energy efficiency, helping you reduce operational expenses.

1

Advanced Vibration Analysis

Identifying imbalance severity and root causes through high-precision diagnostic tools.

2

Using state-of-the-art equipment to correct imbalances and restore optimal performance.

3

Blade & Component Inspection

Examining blades, shafts, and other mechanical parts for wear, misalignment, or defects.

4

Weight Adjustment & Fine-Tuning

Applying precise counterweights to ensure proper weight distribution and minimal vibrations.

Predictive Maintenance for Long-Term Reliability

In addition to fan balancing, we offer predictive maintenance services to help detect early signs of imbalance and wear before they lead to equipment failure. Our predictive maintenance solutions include:

- Vibration analysis & monitoring

- Dynamic balancing & alignment

- Thermal imaging & ultrasound diagnostics

- On-line and off-line motor testing

With SysTech Design, you get precision, reliability, and cost-effective solutions tailored to keep your industrial fans running at their best.

Choose SysTech Design for Expert Fan Balancing Services

At SysTech Design, we are committed to providing top-tier industrial fan balancing and maintenance services. Our team of experts ensures your fans operate efficiently, reducing downtime and optimizing performance. Contact us today to schedule a consultation and improve your system’s efficiency.