Industrial Flexible Connectors

Dynamic stresses caused by vibrations, temperature fluctuations, wind loads, and misalignment can lead to maintenance issues, premature equipment failure, and system downtime in ducted industrial air systems. Flexible connectors also called expansion joints and flex joints, provide flexibility along the duct when connected to rotating equipment by isolating and alleviating these stresses.

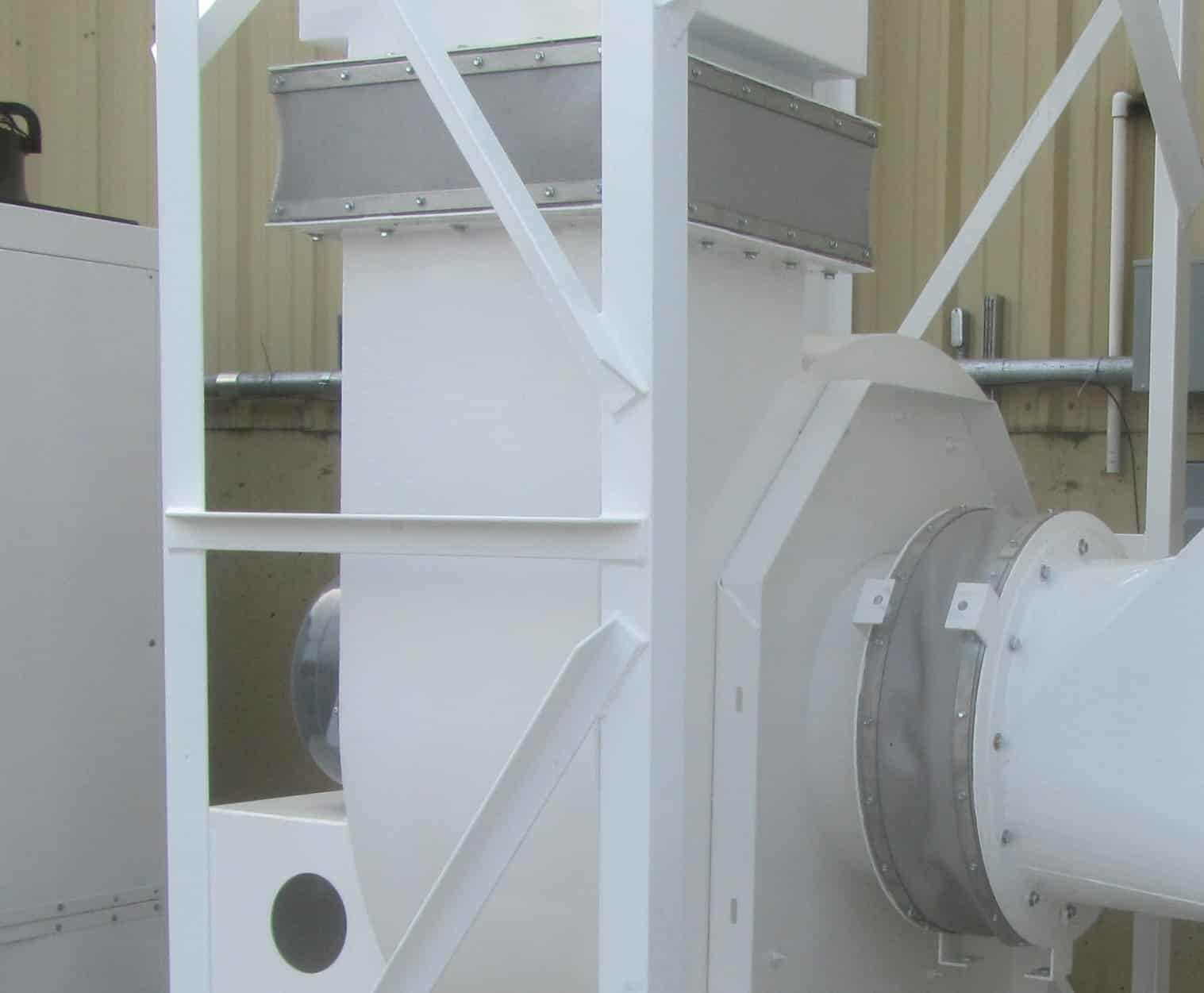

Applications for flexible connectors and expansion joints range from small industrial fans to large utility-grade expansion joints used in air pollution control system ducts and stacks. They are typically found on the inlets and outlets of fans, air handlers, process equipment, and pollution control equipment in many industrial facilities.

Industrial Flex Connectors are designed to handle high temperature, high pressure or vacuum, high material laded airstreams, and aggressive chemicals present in an airstream. The industrial flex connector is typically round or rectangular and is an insertable “spool piece” between rigid industrial air system pieces. Because these are custom designs, size requirements determine if they are shipped as a single piece or in sections designed for field assembly/installation.

When specifying flexible duct connectors, consideration must be given to:

- A review of the axial, transverse, and torsional movement requirements. It is essential to know this information if extreme. A standard flex connector lateral and axial displacement is +/- 0.5 inches.

- The temperature of the airstream is critical as the flex material selection is based on temperature. EPDM with Nylon insert is the standard belt material good to 275° F.

- Pressure-vacuum design is +/- 80 inches WG and is our standard.

- Noise levels – Connectors are a point of breakout noise, and if designing for sound issues, Acoustic Flexible Connectors are an option.

- The abrasive nature of particulate in the airstream is critical because of wear. Interior metal liners are used and may be required.

- Corrosive nature of the airstream – Determines metal selection for the connector flanges, flex material, and liner if required. The selection of a flex material such as PTFE may be necessary.

SysTech can make a flex connector selection for your project, but first, we require some particulars. The attached Flex Connector Questionnaire addresses requisite information that allows us to generate a preliminary selection, or, if we have all the necessary data, a final cost estimate. In some cases, information may not be known, but please provide us with as much detail as possible.

Fan Flex Connector

Fan flex connectors handle high-temperature, high-pressure, vacuum, and material-laded or chemically aggressive airstreams. They are round or rectangular and are aninsertable “spool piece” designed to connect a fan to a duct or equipment flange. Because these are “custom is the standard” designs, special construction requirements typically do not delay shipment. When they are shipped, size requirements determine if they are shipped as a single piece or in sections designed for field assembly/installation.

Parts of a Flex Connector

- Flanges – Either carbon steel, galvanized, or 304/316 stainless steel. “Slip fit” style is an alternative in some cases.

- Flow liners – durable metal liners to protect the flex material from abrasive particulate in the airstream or prevent the belt from being pulled into the airstream when under negative pressure.

- Backing bars – to fix the flex material to the flanges. These are constructed of carbon steel, galvanized steel, or stainless steel.

- Special flange paint – applications above 500° F need to specify high-temperature paints such as carbozinc, good to 750° F.

- Fabric flex materials – Selection based on temperature, with EPDM the standard.

- Acoustic Packing – An option to attenuate breakout noise is fiberglass or mineral wool.

- Gasketing – Must be compatible with the airstream constituents to ensure a low leakage tight seal.

Flexible Connector Belt Materials

Some flex connector belting materials typically used:

High-Temperature Applications:

- The standard EPDM belt is rated up to 275° F.

- Silicone Impregnated Fiberglass belt is rated up to 500° F.

- PTFE belt is rated up to 1000° F.

- Call to review applications above 1000° F.

Corrosive Environments:

- PTFE belt for corrosive environments.

FDA Rated Materials:

- A white PTFE belt with an inner liner is FDA grade approved.

As a system integrator of equipment for industrial ventilation systems that include flex joints, we will work with you to determine the most secure flexible connector for your industrial air system requirements.

SysTech offers the best solutions for all your flexible connectors and expansion joint applications.