Upper Marlboro, MD Industrial Explosion Protection Systems

Industrial Explosion Protection in Upper Marlboro, MD

At SysTech Design, we bring over 40 years of experience providing industrial explosion protection for facilities in Upper Marlboro, MD. Our explosion protection systems safeguard chemical processing plants, food production facilities, and fabricated metal operations from combustible dust explosion risks. We design and install explosion prevention equipment such as explosion isolation valves, explosion suppression systems, and explosion vents to meet NFPA explosion protection standards and OSHA explosion protection requirements, with an emphasis on ease and cost-effectiveness of installation. Each explosion protection system is tailored to the process equipment in your facility, ensuring seamless integration with dust collectors, conveyors, production lines, bucket elevators, and cyclones. Using industrial explosion vent panels, explosion isolation flap valves, and explosion relief panels, we help prevent damage when an explosion occurs. These systems are designed to operate under vacuum and negative pressure conditions. Explosion vents are installed on vessels and other process equipment to relieve overpressure and direct flames, dusts, and combustion gases safely into the atmosphere, protecting both equipment and personnel. Our designs mitigate explosion pressure, protect personnel, and preserve operational efficiency. We also perform a detailed risk assessment to identify dust hazards and engineer systems that keep your facility safe and compliant. Identifying hazardous dusts and managing combustion-related phenomena are critical to preventing fire and overpressure events.

Explosion protection solutions are tailored to the form of the hazard and may include standard vents, flameless venting, or alternative suppression methods. For example, a vent panel installed on a bucket elevator activates at a predetermined pressure, releasing the created fireball into a designated safe area to minimize risk. SysTech Design’s protection solutions are used in installations around the world, including both indoor and outdoor applications. Suppressant agents can be injected into the protected area during the early stages of an explosion to suppress the fire and prevent escalation. After integrating with process equipment, we create barriers to prevent explosion propagation and ensure all areas are protected.

Our Industrial Explosion Protection Solutions

Explosion Isolation in Upper Marlboro, MD

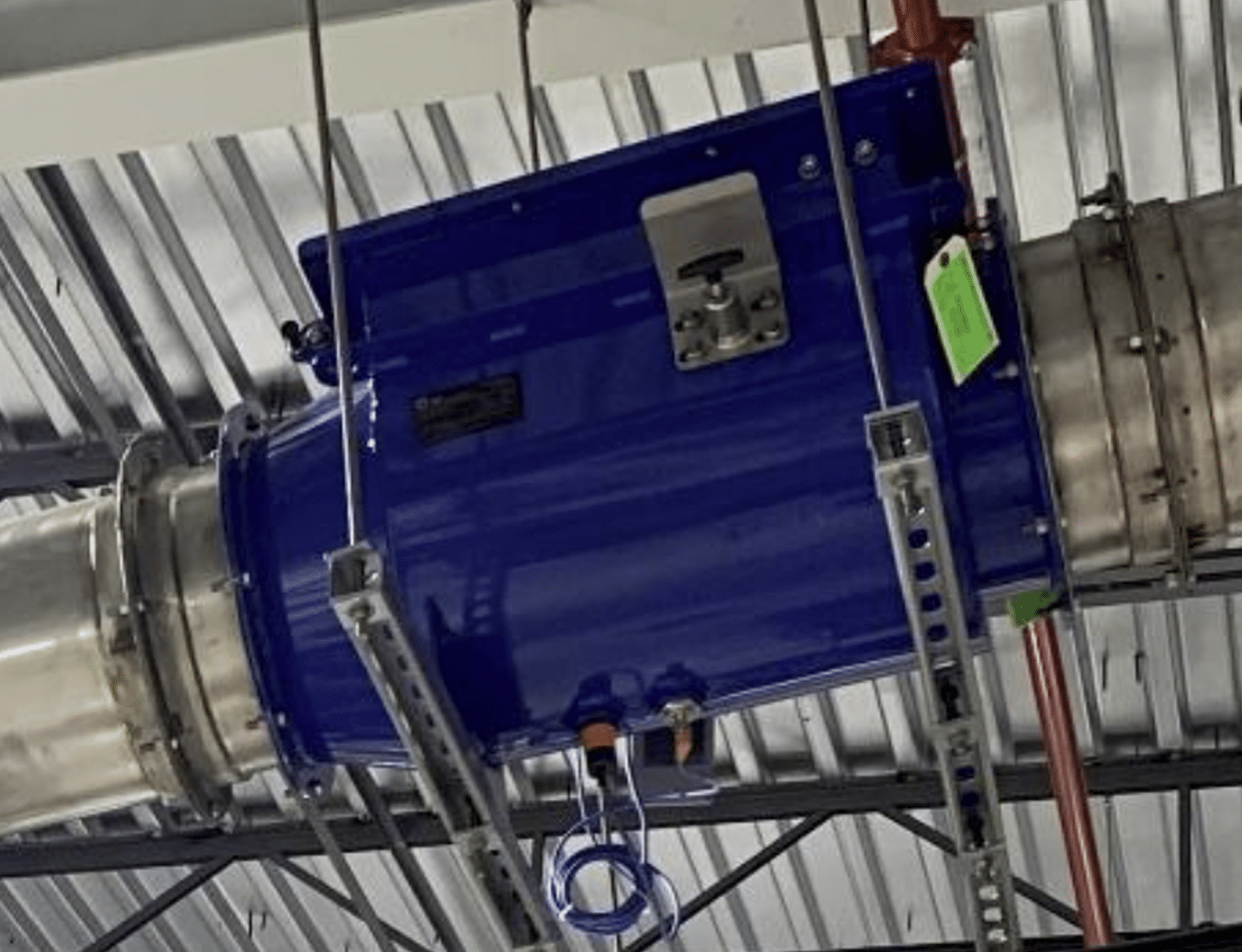

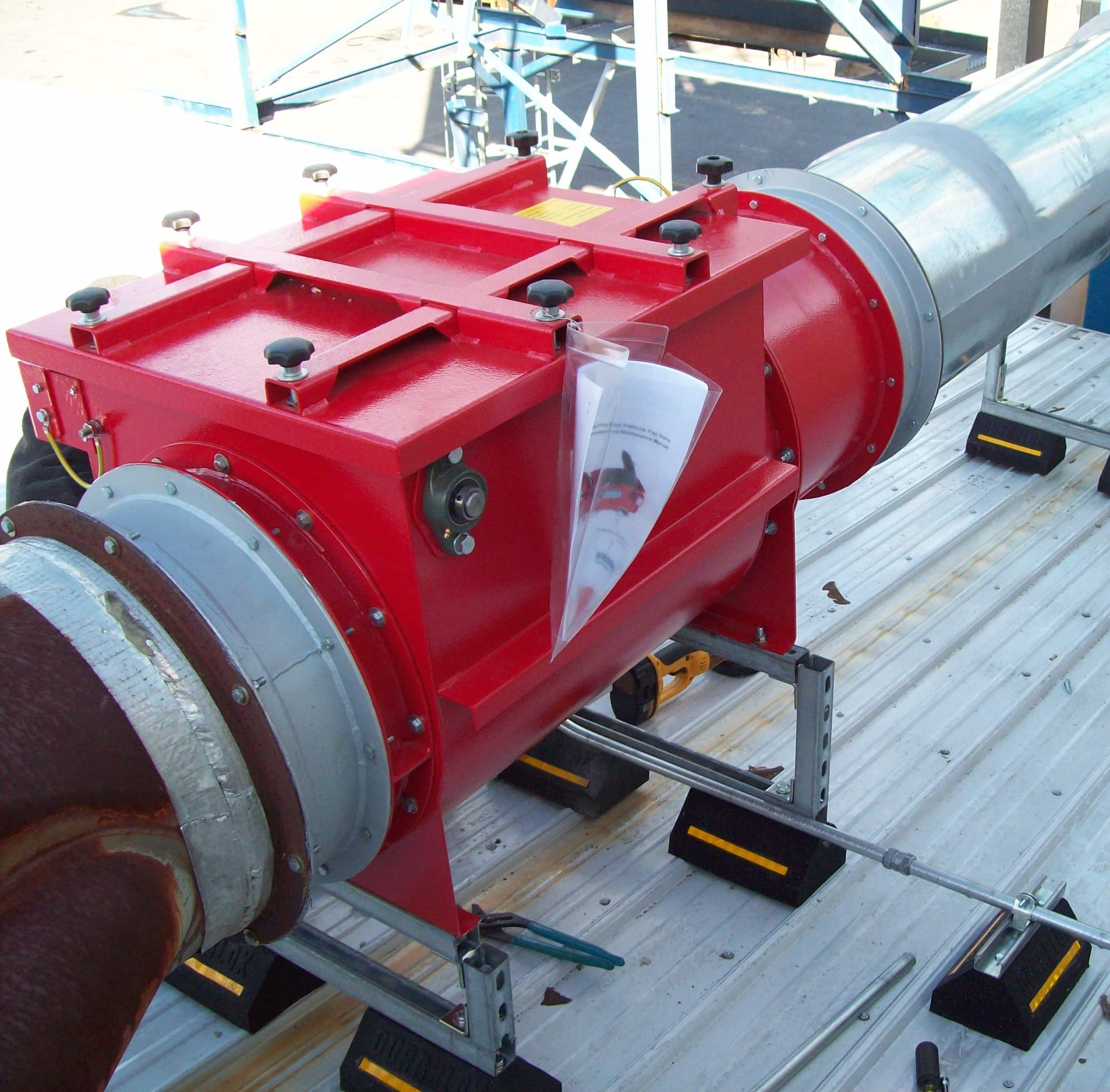

Explosion isolation prevents an initial dust explosion from traveling through connected equipment, which can cause catastrophic secondary events. SysTech Design provides explosion isolation systems engineered to stop the flame front and explosion pressure wave before it can damage other areas. Our solutions protect vital process equipment in chemical, food, and fabricated metal facilities, ensuring compliance with NFPA and OSHA standards. Whether through mechanical or chemical isolation, we design systems to safeguard production lines and maintain worker safety. These systems create a physical or chemical barrier to prevent explosion propagation and enhance overall explosion safety.

- Reduce secondary explosion risks in processing plants – Stops the spread of an initial explosion to other connected areas.

- Protect vital equipment such as dust collectors and conveyors – Prevents severe damage to critical process systems.

- Improve facility safety and regulatory compliance – Meets OSHA explosion protection requirements and industry safety codes.

- Stop explosion pressure waves from spreading through ducts and pipelines – Blocks blast forces from traveling through your system.

Contact us today to see how explosion isolation vents can help contain industrial explosions in Upper Marlboro.

Explosion Suppression Systems in Upper Marlboro, MD

SysTech Design’s explosion suppression systems stop dust explosions in their early stages, minimizing risk to your operations. These systems detect dangerous conditions instantly and, when an explosion is detected, a fireball and pressure wave are created. The suppression system is designed to detect and suppress these immediately. Suppressant agents are injected into the protected area to cool the fire and suppress the explosion. This rapid response helps prevent post explosion fires, equipment damage, and production downtime. For Upper Marlboro’s industrial facilities, our explosion mitigation systems provide essential protection for dust collectors, silos, and other vulnerable process equipment. We use only non-toxic suppressant agents, making them suitable for use in food and chemical facilities.

- Advanced sensors and control units for immediate detection – Identify explosion events in their early stages.

- Ultra-fast response time to stop explosions within milliseconds – Prevents the flame front from spreading.

- Reduced downtime and equipment loss after an event – Maintains production efficiency following an incident.

- Non-toxic suppressants that effectively extinguish explosions – Safe for food processing and chemical applications.

Click the button below to browse our complete selection of explosion suppression equipment in Upper Marlboro.

Explosion Vents in Upper Marlboro, MD

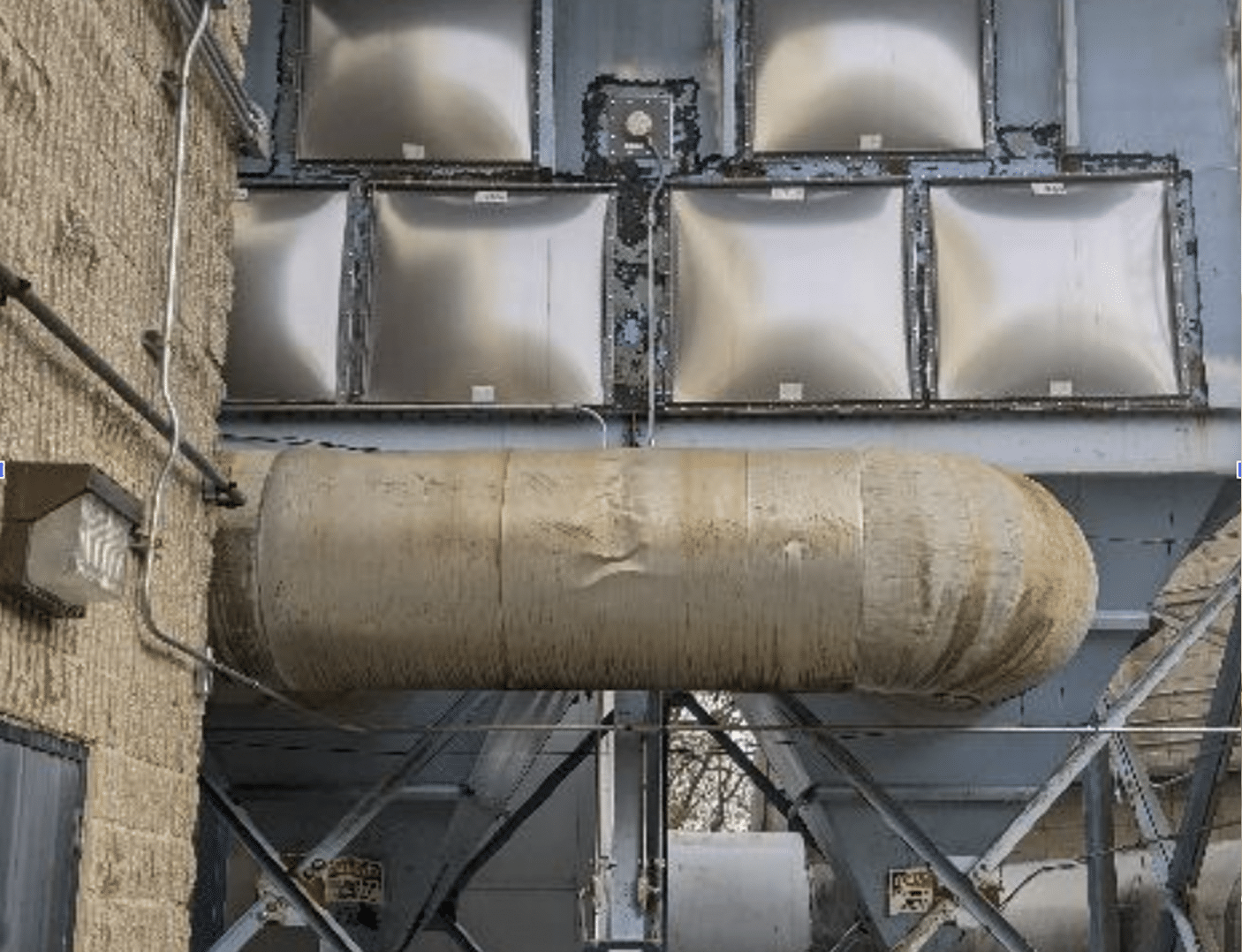

Explosion vents provide a controlled release for explosion overpressure by venting it into the atmosphere, preventing damage to vessels and equipment. SysTech Design designs and installs explosion vent panels and flameless explosion vents, which are installed on vessels, dust collectors, silos, cyclones, and bucket elevators. These vent panels are engineered to evacuate dusts, flames, and combustion gases during an explosion event, ensuring the safety of both equipment and personnel. Standard vents and flameless venting represent different forms of explosion protection; flameless venting is suitable for both indoor and outdoor applications. Vents are engineered to activate at a predetermined pressure and direct the fireball into a designated safe area, minimizing hazards. Explosion vent panels are suitable for installations with vacuum or negative pressure conditions, maintaining safety and durability. For example, a vent panel installed on a cyclone or bucket elevator protects the vessel by relieving overpressure and prevents post-explosion fire by safely evacuating hazardous materials. Our explosion venting solutions meet NFPA explosion protection standards and OSHA explosion protection requirements, ensuring both safety and compliance. SysTech Design offers comprehensive protection solutions for various installations and equipment, including vent panels engineered for static burst pressure control, directing explosive forces away from personnel and equipment. For facilities that require indoor safety measures, our flameless vent options contain the flame while releasing pressure to a safe location.

- Ensure compliance with NFPA and OSHA regulations, standards, or proven strategies – Meets safety codes for industrial applications.

- Prevent catastrophic structural failure in dust collectors, silos, and processing equipment – Releases pressure before critical failure.

- Integrate seamlessly with existing industrial systems – Adapts to current process equipment without major modifications.

- Direct explosive forces safely away from personnel and equipment – Protects workers and infrastructure from blast damage.

Get in touch with us today to request a quote on explosion vents in Upper Marlboro.

The Importance of Industrial Explosion Protection for Upper Marlboro Facilities

Industrial explosions in Beltsville facilities can result in severe injuries, damaged equipment, and costly production downtime. Chemical facilities, food processing plants, and fabricated metal

Industrial explosions can have devastating consequences for Upper Marlboro’s chemical, food, and fabricated metal industries. Combustible dust explosion protection is essential for preventing damage, protecting workers, and maintaining compliance with safety regulations. SysTech Design provides explosion isolation systems, explosion suppression systems, and explosion venting solutions that meet OSHA explosion protection requirements and NFPA explosion protection standards. Our explosion protection equipment suppliers engineer solutions for dust collector explosion protection, process equipment safety, and connected equipment safeguards. With decades of experience, we design industrial explosion prevention systems that control explosion pressure, mitigate dust hazards, and protect your facility from catastrophic events.

Why Choose SysTech Design for Explosion Protection?

Industry-Leading Expertise

SysTech Design is a premier provider of explosion protection systems in Montgomery County. Our team has years of experience and a wide breadth of knowledge.

End-to-End Support

From start to finish, your project will be managed by a single team, ensuring a seamless purchase, delivery, and installation process.

Proactive Compliance

We don’t just help you meet current regulations—we ensure your facility is prepared for evolving safety standards, keeping you at the forefront of innovation and worker safety.

Proven Track Record of Success

From manufacturing to chemical processing, our solutions have protected industries nationwide, delivering measurable safety improvements.

Custom Solutions

We offer custom-designed explosion protection systems for Montgomery County industries, tailored to their unique needs and operating conditions.

Comprehensive Support

From initial hazard assessments and system design to the final installation, we provide end-to-end explosion protection solutions that safeguard your workforce and operations 24/7.

Explosion Protection Solutions We Offer in Upper Marlboro, MD

Combustible Dust Testing

Explosion Vents

Explosion Suppression

Explosion Isolation