Rotating machinery often produces high levels of sound that are easily identified as point sources of noise in a facility. The machine design, materials being processed and location of equipment are all factors contributing to an objectionable noise level.

Noise attenuation for isolated sources is most often addressed with either steel or curtain sound enclosures. These sound enclosures are rooms built around the process. Enclosure design is dictated by overall sound levels, the band frequency analysis, enclosure application and machinery maintenance requirements.

SysTech Design completed two industrial noise control projects with steel walled enclosure solutions having slight variations. The projects required isolation of a hammermill and a planer with both having sound levels around 90 dBA but with differing frequency bands that needed attention.

Industrial Noise Enclosure Designs

Rigid metal noise enclosure surrounding the hammermill that resulted in a 19 dBA reduction of noise levels within the facility.

An Allentown, PA pet food and supply manufacturer contracted SysTech Design to assist them with an ongoing noise issue with a hammermill. Their process consisted of recycling old newspaper and magazines for dog bedding. The hammermill was used to shred the paper products into a smaller usable size. The hammermill emitted a very low frequency sound at the 250 to 500 Hz range and around the 90 dB level. This was very disruptive to the operators and other workers within the facility.

After a detailed analysis of the process and considerations regarding the difficulty of attenuating low frequency sound, SysTech Design offered a rigid panel enclosure consisting of 4 sides, a roof and walk in space. Each panel is 4” thick and has a solid 18-gauge exterior, 4” thick layer of acoustical rock wool and a 22-gauge perforated steel interior surface. The enclosure provided a 19 dBA reduction in sound level in the 500 HZ frequency band. Problem solved!

Noise Attenuation for an Industrial Planer

A specialty plastics supplier located in Eastern Arkansas contacted SysTech Design for assistance in resolving an OSHA directive to reduce the overall sound level within the facility or face implementation of a comprehensive hearing conservation program. This program would require employers to monitor noise exposure levels to identify if employees are exposed to noise levels above 85 dB averaged over an 8-hour time-weighted average (TWA). If monitoring results indicate that employees are overexposed, OSHA requires engineering controls, hearing protection, training and annual audiograms be implemented.

After a thorough review of the 12,000 square foot facility, it was determined that a large sheet planer, which is located in the center of the plant, was the main source of the high frequency, high dBA sound. When operating, the sound levels within the facility ranged from 82 to 91 dBA. When the planer was shut down between shifts, all readings were less than 75 dBA.

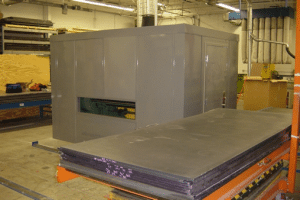

Acoustic enclosure implemented to decrease noise levels created by an industrial planer.

SysTech Design recommended a rigid enclosure that consisted of solid 18-gauge steel exterior and a 22-gauge perforated steel interior with 4” thick rock wool packing. Access doors and service panels were included along with the material inlet and outlet openings.

The enclosure resulted in 12-15 dBA sound reduction, which reduced sound levels to permissible OSHA limits. SysTech Design not only provided a solution to the noise problem, but also saved the employer several thousand dollars that they would have spent to implement a hearing conservation program.

Let SysTech provide the right design and products for your noise control requirements. Contact us today at 800-456-9460 to get more information.