SysTech offers both cost-effective and compliant explosion protection and prevention system. SysTech Design and IEP Technologies, through our knowledge and experience, can help you navigate frequently updated Recommendations and Standards to ensure that your manufacturing processes and workers are protected from the threat of a combustible dust or hybrid (vapor and dust) application explosion and explosion risk minimized.

Industrial explosion protection systems designed to address combustible dust and hybrid applications are what we do. The explosion protection plan of action that we implement is based on the potential severity and proper mitigation of, dust, and hybrid dust that might result in a catastrophic event. From initial dust testing, equipment selection, final installation, and periodic maintenance services for your explosion protection system, SysTech will be available to answer your questions and provide the support you need.

“SysTech’s goal is the implementation and Integration of compliant explosion protection systems to protect against combustible dust and vapor applications to meet all applicable NFPA Standards.” – Adam Conley 2005

If you’re updating, expanding, or changing the application for an existing system we can provide the necessary support. We retrofit and update equipment from many manufactures to meet Code and have installed explosion suppression systems, explosion vents and NFPA approved accessories on over 10 different manufacturers of dust collectors. Before you replace a piece of equipment let us see if it can be updated and modified to NFPA criteria before a major capital expenditure.

The Combustible Dust Threat and NFPA 652

Since the 2003 US Chemical Safety Board hearings and the 2007 OSHA Combustible Dust National Emphasis Program (NEP), Dust Hazard Analysis (DHA) has risen to a top priority for plant safety reviews. This has resulted in an ever-increasing demand for effective explosion protection systems and a growing awareness of workplace health and safety hazards.

To address combustible dust explosion, NFPA issued Standard 652, Standard on the Fundamentals of Combustible Dust, 2016 edition. Official document scope is “This standard shall provide the basic principles of and requirements for identifying and managing the fire and explosion hazards of combustible dust and particulate solids.” This Standard places responsibility for knowledge of the dust (the Dust Hazard Analysis) squarely on the facility management with a retroactive date of October 2018 to comply.

Combustible dust management includes protection against primary explosions within a process and against secondary explosions resulting from inadequate housekeeping or nuisance dust accumulation. The primary explosion will shake loose other dust that has accumulated, most often, on horizontal surfaces. When this dust becomes airborne, it also ignites. This secondary dust explosion is often more destructive than the primary one.

Applications where Combustible Dust Issues are Prominent

Explosion mitigation should be investigated for the following processes and equipment (not an all-inclusive list):

- Conveying Equipment – Elevators, Pneumatic Ducts, Separators, Vapor Control

- Processing Equipment – Coaters, Cookers, Dust Collectors, Dryers, Paint Booths, Sanders

- Pulverizing Processes – Ball Mills, Cage Mills, Flakers, Granulators, Grinders, Shredders

- Storage Vessels – Bins, Cyclones, Flammable Liquid Storage Areas, Hoppers, Tanks

Significant Explosion Mitigation Techniques

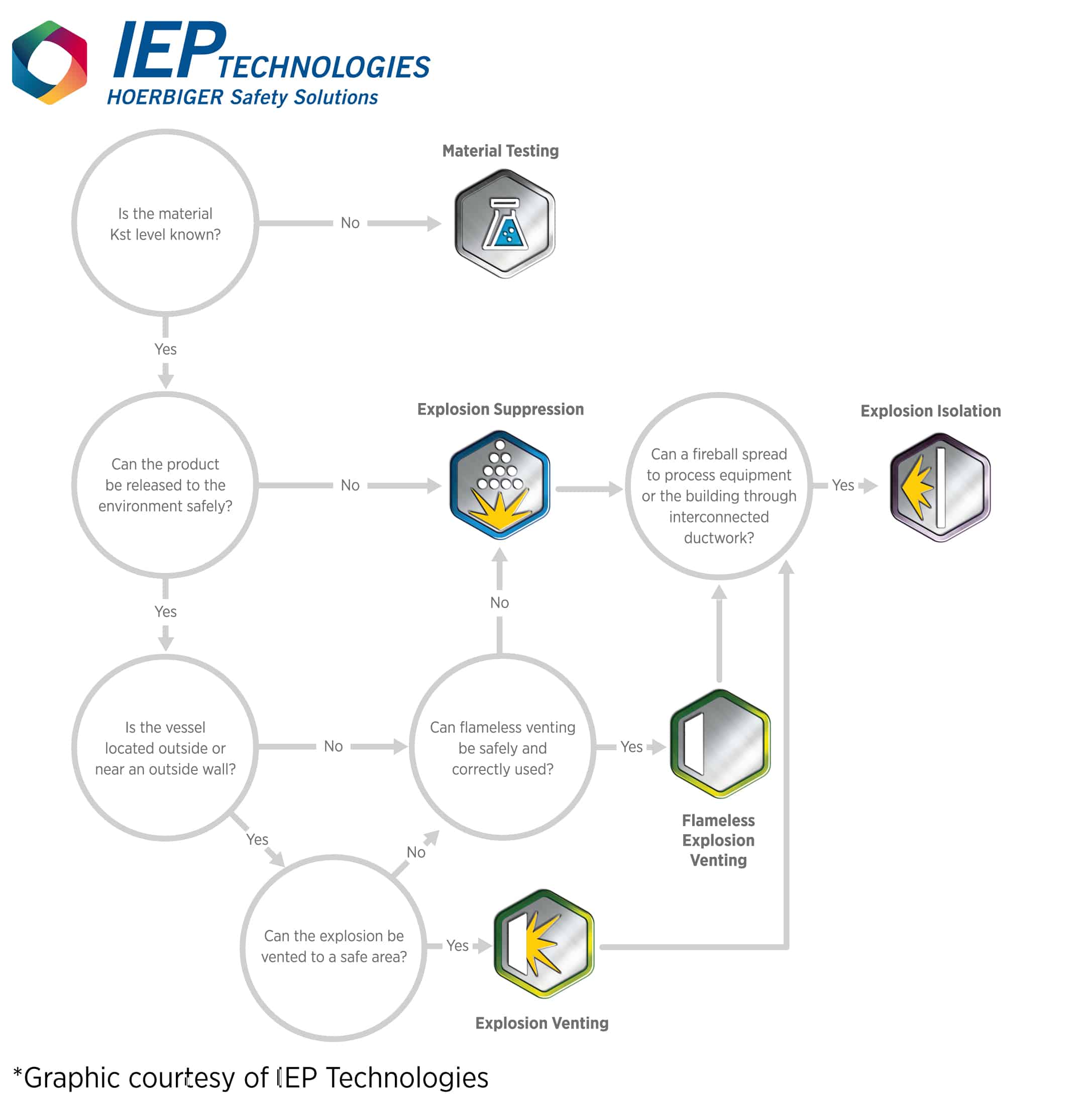

Explosion protection systems address containment or mitigation of potential explosions through the following means:

- Explosion Venting – Relieves the vessel/enclosure pressure and redirects or arrests the fireball associated with an explosion (Compliant with NFPA 68)

- Explosion Suppression System – Suppresses potential explosions through the discharge of chemical agents (Compliant with NFPA 69, 654, and 652)

- Explosion Isolation – Prevents explosions from propagating through ductwork and spreading throughout the facility or to other pieces of equipment (Compliant with NFPA 69 and 654)

- Combustible Dust Testing – Part of the Dust Hazard Analysis (DHA) as outlined in NFPA 652

- Static Charge Dissipation – Eliminating the ignition hazards of static electricity

- Spark Detection & Extinguishing – Designed to mitigate fire and explosion events

Active or Passive Explosion Devices

Explosion protection equipment and systems are defined as either active or passive in design. Passive devices do not require a detector to activate the device. Explosion vents or panels are passive as are mechanical isolation valves such as the ProFlap Plus III and the VENTEX valve.

Chemical suppression and isolation systems using PistonFire II Suppressor bottles are active as are slide gate knife isolation valves. In this case, when explosion pressure builds and sensed, a remote detector sends a signal to the selected devices. An explosion protection system can be totally passive or active depending upon the facility regulations and position of the protected equipment within the facility. Typically, active systems will be a more defined design based upon equipment being located indoors or not being able to be properly vented to the atmosphere safely.

NFPA Standards Applied to Combustible Dust

Whatever your final design and equipment selection, it is imperative to know who will approve or certify the system you select when your system is in operation. That party is defined as Authority Having Jurisdiction (AHJ) and they most often will refer to the latest version of the NFPA Standard.

Key standards seen in industrial ventilation systems include the latest edition of:

NFPA 660: Standard for Combustible Dusts and Particulate Solids – This standard, adopted December 2024, consolidates* NFPA 61, 484, 652, 654, 655, and 664 within one combustible dust standard and is intended to clarify and simplify means to combustible dust safety practices that include dust hazard analysis, dust control, ignition source control, explosion protection design, and compliance and testing.

NFPA 61*: Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities – An industry-specific Standard that is directed at protecting Agricultural and Food Processing Facilities. It focuses on methods of safely handling agricultural dust, by-products, and related materials through maintaining certain safety precautions in regard to their storage, handling, and processing.

NFPA 68: Standard on Explosion Protection by Deflagration Venting – This Standard defines methods for implementing explosion vents or systems to decrease pressures within a dust enclosure to minimize damage, should flammable vapors or dust be ignited.

NFPA 69: Standard on Explosion Prevention Systems – This Standard serves as a design manual for designers or AHJs who are responsible for explosion prevention systems implemented on process systems that may produce flammable gases, dust, or hybrid mixtures within an enclosed environment such as a dust collector, receiver or elevator.

NFPA 77: Recommended Practice on Static Electricity – This document identifies processes that pose electrostatic discharge potential and offers practical measures to mitigate.

NFPA 91: Standard for Exhaust Systems for Air Conveying of Vapors, Gases, Mists, and Particulate Solids – This Standard provides technical requirements for exhaust systems that will protect lives and property from fires and explosions and minimize damage in the event that such fires and explosions occur.

NFPA 484*: Standard for Combustible Metals – This industry-specific Standard applies to those manufacturers involved with processing, finishing, and recycling of metal or metal alloys that generate a byproduct of fugitive combustible powders or dust and are capable of an explosion.

NFPA 652*: Standard on the Fundamentals of Combustible Dust – This Standard defines the key elements of potentially combustible dust explosions or fires and the necessary mitigation procedures to avoid them. It acts in conjunction with industry-specific Standards by allowing them to prevail in specification conflict.

NFPA 654*: Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Solids – This NFPA Standard is written in regards to the prevention and mitigation of explosions or fires for all combustible solids in particulate sizes including dust, fibers, chips, and chunks.

NFPA 664*: Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities – This industry-specific Standard details mitigation techniques for the wood processing and woodworking industry to protect against fire and explosion.

Should your AHJ require additional documentation, SysTech can provide a Combustible Dust Testing and recommend a Risk Assessment Consultant to evaluate and document the existence or non-existence of dust hazards within your facility.

Explosion Protection Systems Manufacturers

We are your representative for IEP Technologies | HOERBIGER Safety Solutions (formerly Fenwal Protection Systems), the largest fire and explosion protection company in the world.

IEP Technologies | HOERBIGER Safety Solutions

IEP Technologies joined with HOERBIGER Safety Solutions and continues as the foremost authority on, and innovative developer of, explosion protection equipment and systems. Formerly, Fenwal Protection Systems, their history of supplying explosion protection systems dates back to1950.

Their knowledge of explosion mitigation is augmented by more than 20 years of industry experience with a full line of explosion panels both in rectangular and round configurations.

Atexon | HOERBIGER Safety Solutions

A HOERBIGER Safety Solutions company spark detection and extinguishing system designed to detect ignition sources such as hot particles and embers. Atexon is applied where a potential fire or explosion event is probable.

Newson Gale | HOERBIGER Safety Solutions

Part of the HOERBIGER Safety Solutions group of companies. Newson-Gale designs static control for hazardous areas through grounding and bonding. They develop and manufacture hardware solutions focused on eliminating the ignition hazards of static electricity in both flammable and combustible atmospheres.

SysTech through its knowledgeable manufacturers offers the best in explosion protection systems and explosion protection services.

Case Studies

- Candy Maker Retrofits Dust Collection Systems with Explosion Suppression and Isolation

- Dust Control for a Garnet Blasting Operation

- Dust Filtration System Handling Explosive Materials

- Explosion Protected Portable Pharmaceutical Dust Collector

- Flex Connector in Explosion Suppression System – Don’t Even Think About It*!

- How Soon Can I get an Explosion Vent?

- Hybrid Mixture Dust and Explosion Mitigation

- Industrial Dust Collection System Increases in Size and Decreases in Cost

- Need Custom Explosion Vents ASAP?

Optional Explosion Protection Walkthrough, Inspection or Troubleshooting

We can help remotely if needed! Industrial Explosion Protection walkthroughs will help us to better understand the magnitude of the Explosion Protection issue and important space constraints that might inhibit a specific mitigation technique.

Let SysTech be part of your Explosion Protection Solution

SysTech is experienced in developing industrial explosion protection solutions for a wide range of industrial environments. Call SysTech to discuss your Explosion Protection needs.