Particle size, enclosure volume, present spark sources, and dust concentration all impact the susceptibility of a system to a combustible event. It’s known that flour, coal, and wood are potential hazards, but so are metals. Metals can be very dangerous and challenging due to the temperatures they burn at which can be 2.5 times hotter than other organic materials. How do you know if your dust is combustible? You don’t until you get it tested!

Equipment and systems that handle materials classified as combustible dust must be protected under current OSHA and NFPA Standards. SysTech provides dust collectors, vacuum systems, process vessels, and material handling systems that include integral explosion protection with specific components designed for the location, explosivity of the dust, and the equipment’s structure. We can only do that if the dust characteristics are identified before the system is designed. Caution must be exercised if a dust collector or vessel handles newly unknown dust or if an existing piece of equipment is moved to a new location in or around a facility.

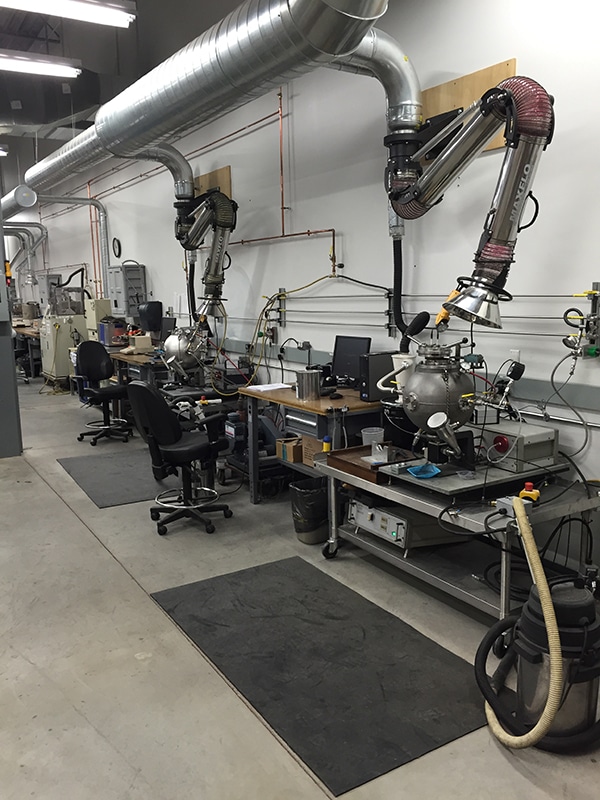

Our explosion protection systems include isolation flap valves, knife gate valves, float valves, explosion vents, chemical suppression systems, and flameless explosion vents.

Code officials and corporate health and safety personnel are looking closely at systems where combustible dust is or may become a significant hazard in both process equipment and dust that has accumulated on interior horizontal surfaces. NFPA has developed a series of Standards for protecting equipment and, subsequently, people and facility processes. These need to be used when reviewing your system.

SysTech has the equipment to address in-place systems and new equipment installations. We adhere to the NFPA Standards 68,69, 652, and 654 as well as those NFPA Standards for specific applications such as NFPA 484 for Metal Dusts to keep your facility and processes in compliance and safe. We can suggest steps that are needed right away but can only give you the required direction after your dust is tested. Combustible dust testing will provide the information we need to formulate the appropriate explosion protection system.

The safety of your people and facility may be at risk. Simple to address, and we can help you with that. Call us about Remote Walk-Thru, a remote virtual support service, and we’ll review your application together.